Table of Contents

SEGs: The Foundation for a Great IH Program

For this first session of our IH 101: Introduction to Industrial Hygiene Program Management series, we’re going to take an in-depth look at similar exposure groups (SEGs) to help you understand their critical importance to your IH program. We’ll also offer common-sense guidelines for how to set up your SEGs and explain how they fit into your overall IH program structure.

Before we begin, it’s important to keep in mind that SEGs are just one of several moving parts that make up an effective IH program. QEAs, sampling plans, lab analysis, data analytics and reporting systems, medical surveillance and program evaluation are all fundamental components of your IH program — each deserving equal focus and careful coordination to ensure optimum program performance.

We recommend reviewing our IH Program Cycle Infographic and IH Program Guide to help you establish a basic understanding of overall IH program structure.

What are SEGs?

Numerous OSHA Standards and other workplace exposure standards require companies to evaluate the health risks of their workers, and ensure they are controlled to a safe level. These evaluations are most commonly performed through qualitative risk assessments (QEAs), or through quantitative measures such as air monitoring of individual worker exposures.

But there’s a problem – how can a company expect to accurately evaluate and manage workers’ health risks when they have 100’s, 1,000’s, or 10,000’s of employees? Performing risk assessments and sampling on each individual worker would be far too time consuming and costly, exceeding even the largest of EHS budgets. So, how do we evaluate workplace exposures and ensure the health of all workers while making the most efficient use of our time and resources? SEGs are the answer.

Similar exposure groups (SEGs) rely on the principle of grouping workers into job profiles, and assessing the health risks to those workers based on similar exposure conditions. Hence, similar exposure groups. SEGs are commonly defined using any combination of exposure characteristics, including:

- Location

- Job

- Task

- Equipment used in the process

Let’s work through an example to help illustrate the steps in creating a SEG.

Say that our Houston Refinery has 250 employees that work as Operators, Administrative Staff, Maintenance and other key functions to operate the plant. Following a site tour and detailed discussions with experienced EHS professionals at the plant, we find that only 5 groups of workers have any significant exposures. These 5 groups are identified and formed into SEGs.

By grouping workers based on similar exposure, you’ve already dramatically reduced your risk assessment and sampling efforts by focusing on these 5 groups, rather than on all 250 employees individually.

Why are SEGs important?

Quite simply, SEGs are the foundation of any IH program. Once established, they offer a more convenient, easier-to-understand visualization of workplace job tasks and operations, and their associated exposure risks.

Efficiency

Perhaps the greatest advantage of SEGs is that they allow you to optimize your sampling activities by using data from a relatively small number of samples from the exposed population to accurately predict exposures to a wider population of workers. The information can also be used to compare exposure risks with other similar SEGs at other locations. Once a SEG’s baseline exposure is established, the information allows you to more effectively allocate and prioritize exposure monitoring and control efforts, ultimately saving you significant amounts of time and resources.

Reducing Complexity

SEGs can also be used to better manage risk profiles for workers who perform a variety of job tasks throughout the day and may be exposed to multiple workplace stressors. For example, the average exposures for a shift (8-hour TWA) can vary widely depending on the time spent performing specific tasks. Identifying SEGs for specific tasks provides better visibility of which tasks present exposure risks, which then provides a more accurate determination of what controls, if any, need to be implemented.

Improved Communication

Creating SEGs also helps to facilitate greater visibility and continuity of your IH program. In the past, IH programs relied heavily on the professional judgement or experience of a seasoned IH professional. Over the course of years, these IH pros familiarized themselves with the jobs and tasks that had the highest exposure risks, and simply knew where to prioritize their sampling and assessment activities.

Unfortunately, this knowledge was not well documented and existed as a loose collection of sample data and other records stored in spreadsheets or simple database software. As those IH professionals retired or transitioned away from the role, incoming IH managers then have to analyze the data to figure out the status of the IH program, including what sampling was being done, why it was being done and where the exposure risks are.

Creating SEGs enables continuity and transparency of the knowledge gained through years of experience — knowledge that can be easily transferred and referenced by the new IH manager or EHS professional responsible for IH program management.

When communicating the exposure risks to workers or management, they will prefer to have the data summarized by the job profile or the tasks being performed. This also enables controls to be specified at a job or task level. For example, all Operators conducting liquid sampling in Unit 1 should wear ½ mask respirators. This control protects all workers performing the job and task, rather than just the individual worker that was sampled.

One of the biggest benefits in developing SEGs is to have a consistent characterization of the workplace and identify any groups of workers that have a potential for overexposure. So, when the IH with 30+ years of experience and knowledge at that plant retires, they can hand over the keys with all of that knowledge documented in a manner that can be easily utilized and managed.

How do I Create SEGs?

Many EHS professionals are apprehensive to define their SEGs without a lot of supportive sampling data. I believe this is the wrong approach, and actually erodes the benefits of creating SEGs.

Don’t be worried about being 100% accurate on identifying your SEGs on your first round. This is an iterative process that takes time to fine-tune. The most important thing is to just get started. Start developing your SEGs by first observing the workers at your site and asking questions like:

- What common jobs/roles are workers placed into? (e.g. Operator, Maintenance, Electrician, Pipefitter)

- What tasks do they perform that create potential health risks/exposures? (e.g. welding, liquid sampling, opening vessels)

- Are there different methods or equipment used for similar tasks that effect the exposure risks? (e.g. open vs. closed systems, new vs. old equipment that hasn’t been properly maintained, etc.)

- What stressors are the workers potentially exposed to at their job or during the tasks? (e.g. noise, benzene, asbestos, lead, etc.)

If you have experience at your site and know the operations closely, you can build an initial list of SEGs even before you go out into the work environment. If you don’t have that degree of familiarity, you will need to spend more time directly observing the workers at your site. Remember, the goal is to get started, not to be 100% accurate on your first attempt.

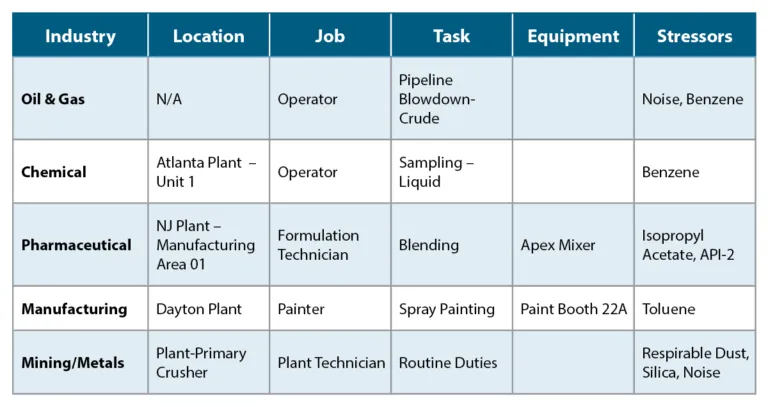

Here are some common examples of SEGs for various industries:

For instance, SEGs in most manufacturing environments can be characterized by a combination of location, job and task – but other industries may not require all of these attributes.

Industries with highly distributed work sites like oil & gas pipeline transmission typically don’t need to assign a location to their SEGs. The table above uses the example of a Pipeline Operator performing a blowdown of a pipeline containing crude oil. The potential for exposure to noise and benzene during this task is consistent regardless of their location, so it is not specified. This will save us from having to perform air monitoring at every location where the Operators perform blowdown procedures on the pipeline, and can help minimize the number of SEGs you ultimately need to create.

If you are feeling overwhelmed by the number of potential SEGs at your facility, you can break it up into different phases. A common approach is to start with full shift exposures (i.e. no tasks – all full shift TWAs), then identify the task, then maintenance activities. I have seen companies take this approach until they are confident they have appropriately assessed the full shift exposures. In reality, it may take a year or two to expand the scope of your SEGs to include tasks and maintenance activities.

Again, the most important step is to just begin this process, and continuously improve your SEGs over time. Rome wasn’t built in a day, and neither is a highly effective IH program.

You can access AIHA’s downloadable spreadsheets that help in documenting the SEGs.

VelocityEHS Can Help!

Our IH Solutions give you an IH program management software system that is purpose-built to coordinate and maintain a comprehensive IH program built on AIHA best practices. Designed by our in-house team of Certified Industrial Hygienists (CIHs), VelocityEHS IH Solutions help you easily assess and control workplace stressors, automate time-consuming IH program tasks, and maintain a world-class IH program no matter what your level of IH expertise. Visit our IH Solutions Page to Learn More!

Ready to see for yourself how VelocityEHS can help you revolutionize your IH program? Contact Us or Request a Demo today!