In Part 2 of our blog series on Industrial Hygiene Program Management, “QEAs: The Foundation of a Great Industrial Hygiene Program”, we learned the standard and most widely used methodology for performing qualitative exposure assessments (QEAs). This step of performing the risk analysis is a pre-requisite to developing your IH sampling plans in a way that effectively targets priority exposure risks in your workplace and makes the most from your sampling time and resources.

Before you read on, we strongly recommend reviewing Part 1 on SEGs, as well as Part 2 on QEAs, and downloading our IH Program Cycle Infographic and IH Program Guide on the 7 steps to effective industrial hygiene (IH) program management. These resources will provide you with the necessary background to get the most from our discussion on IH sampling plans.

What is an IH Sampling Plan?

An IH sampling plan is essentially the ‘to-do’ list for your IH sampling activities. Your sampling plan will list the number, type and details of samples that must be collected for each SEG and stressor of concern. It provides a clear list of the samples needed throughout the year. Once your plan is defined, it provides the added benefit of being able to track performance against sampling plan completion.

A comprehensive sampling plan will address the following questions:

- What regulatory-driven periodic sampling is required?

- What SEGs need additional monitoring?

- How many personal, area, wipe or other type of samples are needed to improve the precision of your QEAs?

- What is the deadline to complete the samples?

Like any to-do list, you want to continually re-evaluate your sampling plan to ensure that the sampling activities you plan to accomplish are the ones that actually need to be done to meet your compliance requirements and best protect worker health. So, ask yourself a few questions:

- Are you following the same plan that was established by a previous IH manager years ago?

- Is your IH sampling simply reacting to employee or business concerns?

- How do you know if you are you sampling too much, or not enough?

In this article, we will cover a simple and effective method you can use year-over-year to define a sampling plan that focuses your resources to get the most out of your effort and support the overall IH program.

Sampling Plans as Part of Your IH Program

Developing SEGs and performing QEAs are critical to establishing baseline assumptions of workplace exposure risk, but your sampling plan is the critical next step that enables you to validate and fine-tune those assumptions. Once developed, your sampling plan provides you with a comprehensive and visual breakdown of the potential risks in your workplace so you can get to the important work of protecting workers.

Here are some of the greatest benefits of establishing a sampling plan:

- Compliance: Some industries and regulatory standards require sampling be performed on a periodic basis, (e.g. quarterly). Having a defined plan and tracking the status against your plan provides an easy means of demonstrating compliance.

- Prioritization: Using the sampling plan methodology prescribed below, you’ll ensure you’re addressing the highest priorities with consideration for your annual IH program budget.

- Quicker & cheaper: Your sampling efforts will be focused on the exposure risks that need additional data. For example, the annual noise surveys you’ve conducted every year that consistently show noise levels are still above 95 dBA can be removed or greatly reduced. The goal is to minimize the overall number of samples you must collect, saving you money and giving you back time to focus on more important projects.

- Improved communication: A well-developed sampling plan can be a great tool to show workers and management what samples are needed and why. This simple form of communication will help secure budgeting and gain buy-in from management, workers and other IH program stakeholders.

- Litigation Support: Sampling plans help you establish a well-documented IH program. The information in your sampling plan can provide faster access to supporting data without needing to recall files from storage and spend weeks going through old reports.

- Knowledge Transfer: Using the methodology described below, future IH/EHS professionals responsible for leading your program will be able to understand the reasoning behind previous sampling plans.

How do I Develop a Sampling Plan?

Step #1: Identify any Regulatory-driven Periodic Sampling Requirements

OSHA and other agency standards include regulatory-required periodic sampling that must be considered when developing your sampling plan. One example is the Coke Oven Emissions Standard, 29 CFR 1910.1029. Paragraph (e)(1)(iii) of the Standard requires the full-shift personal sampling for each battery and job classification on each shift. This sampling is to be conducted quarterly.

Start your sampling plan by making a list of the sampling required for each SEG, stressors that must be assessed, how many samples are required, and the date(s) they need to be completed.

Step #2: Identify Samples Needed to Increase Confidence with Your QEAs

In Part 2 of our blog series on Industrial Hygiene Program Management, “QEAs: The Foundation of a Great Industrial Hygiene Program, we showed an example of how to perform QEAs for SEGs identified at the Houston Refinery. We’ll with this example in developing our sampling plan.

AIHA has developed a simple formula that we recommend to our customers when determining priority for additional investigation, including additional sampling activity. The formula is:

Info Gathering Priority Rating = Risk Rating X Uncertainty Rating

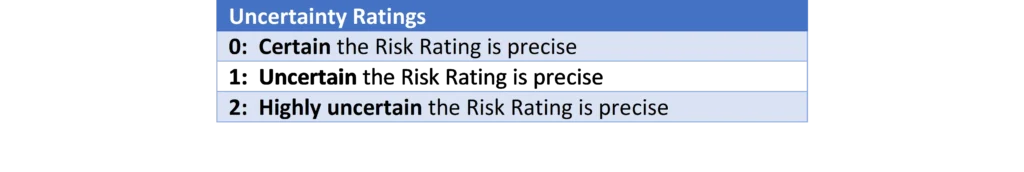

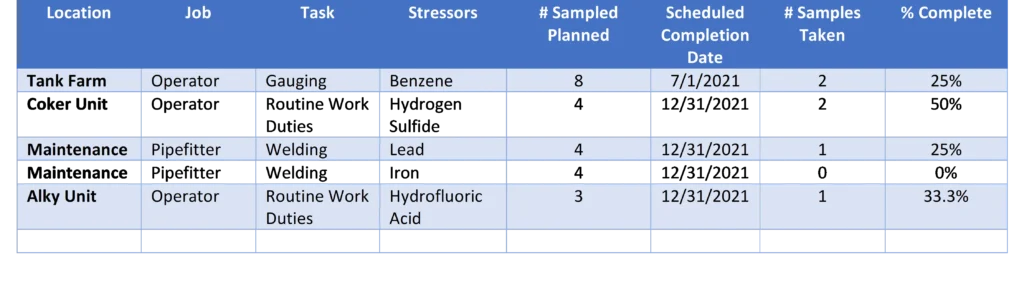

The Risk Rating was previously determined when we performed our QEA (See Part 2 for details). The Uncertainty Rating is based on the following options:

In Table 1 below, we added two columns to the QEA table used in our QEA (see Part 2) that will be used for the Uncertainty Rating and Info Gathering Priority Rating. We then sorted the table by highest Info Gathering Priority Rating.

Table 1: QEA with Risk Uncertainty and Information Gathering Priority Ratings

The ranking of the priority items provides a good roadmap where resources should be focused to improve the confidence of your QEA Risk Rating.

Based on information in Table 1, we see the highest priority is the benzene exposure while gauging a tank in the tank farm. There are also four others with ratings greater than zero (i.e. have some degree of uncertainty) and six with a zero rating (i.e. a high degree of certainty).

Items with a zero rating have the lowest priority, but should be periodically be re-evaluated to confirm the exposure potential hasn’t changed.

Step #3: Document the Sampling Plan

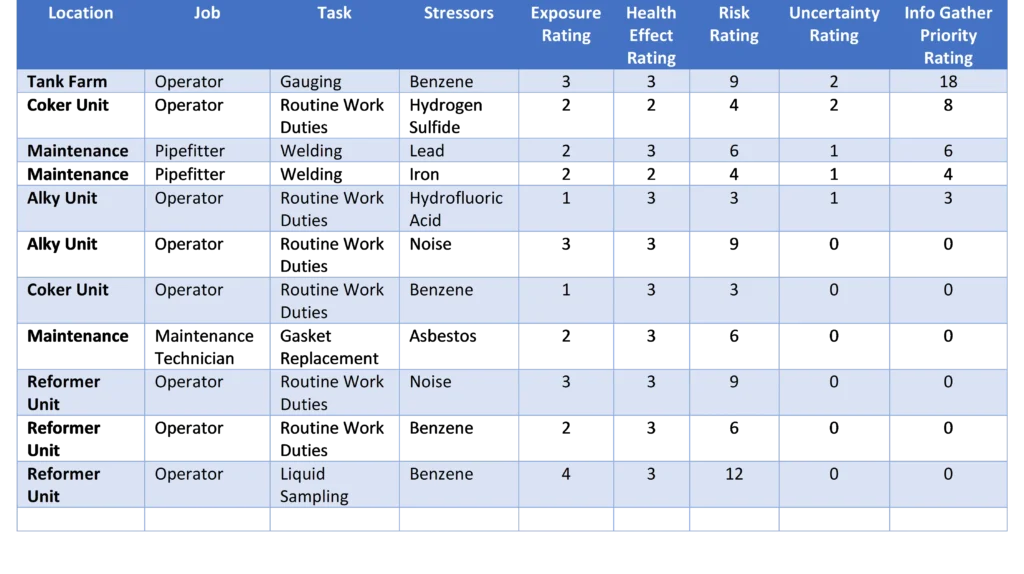

Once you have the regulatory-required sampling and the prioritized list SEGs that require additional sampling, you can combine them in a single table and determine the number of samples to take and the scheduled completion date(s).

How many samples are needed?

There are a lot of different strategies and methods that can be used to determine the appropriate number of samples to take — too many to discuss all of them here in the is article. Ultimately, most of these methods recommend between 3 and 9 samples for each SEG/stressor. We will go into more detail on this topic on Part 5 of our seven-part series on IH Program Management – Data Analysis.

What should I set as the scheduled completion date?

December 31st is the most common date, since most sampling plans are annual. However, make sure you meet the time requirements/deadlines for your regulatory-required sampling. (For example, if quarterly monitoring is required, show the line item 4 times with the end of each quarter as your scheduled completion date)

You may also set the date earlier in the year if there is a high potential for exposure that is not well understood, or to match up with your production calendar when the task is being performed.

Once the plan is established, you can track the progress through the year by adding columns for # Samples Taken and % Complete. An example of finished sampling plan is shown below in Table 2.

Table 2: Sample Plan Example

Final Notes

Remember, a sampling plan is just a plan. There will be times when you need to adjust the plan or collect additional samples. Your plan needs to remain flexible to adjust for changes change in process, stressors or to validate effectiveness of exposure controls. Additionally, we must address employee concerns that are raised and may impact our info gathering priorities.

Next Time…

In Part 4 of our IH 101 series we’ll explore best practices for how to work with your laboratory as a partner to ensure you are receiving the greatest benefit, and how working with an IH software system that supports laboratory interfaces facilitates that partnership.

Additional IH Program Resources

Sampling Plans are just one of the many moving parts that make up an effective IH program. Your SEGs, QEAs, lab analysis, data analytics and reporting systems, medical surveillance and program evaluation processes all deserve equal focus, and should be carefully coordinated to ensure optimum IH program performance.

Our certified IH experts have recently developed two new complimentary resources. The IH Program Cycle Infographic and IH Program Guide will guide you in the 7 steps to applying a proven, process-based framework for your IH program built around continuous improvement principles and AIHA best-practices.

In the Meantime…

VelocityEHS IH Solutions give you a software system that’s purpose-built to coordinate and maintain a comprehensive IH program founded on AIHA best practices. Designed by our in-house team of Certified Industrial Hygienists (CIHs), VelocityEHS IH Solutions help you easily assess and control workplace stressors, automate time-consuming IH program tasks, and maintain a world-class IH program no matter your level of IH expertise. Visit our IH Solutions Page to Learn More!

Ready to see for yourself how VelocityEHS can help you revolutionize your IH program? Contact Us or Request a Demo today!