On May 3, OSHA held a public hearing on “Protecting Workers from Heat-Related Hazards” to summarize the Administration’s current efforts to reduce incidence of heat-related illnesses, and to allow stakeholders to provide feedback. This hearing came at an important time, given that OSHA is currently prioritizing heat-related hazards in its enforcement activities, and has made its intentions clear to develop a heat exposure standard.

In what follows, we’ll give you the information you need about the background of OSHA’s plans to further protect workers from indoor and outdoor heat exposures, the key topics addressed at the recent public hearing, and the main takeaways.

The Background of OSHA’s Activities on Heat Exposure

According to the U.S. Department of Labor’s Bureau of Labor Statistics (BLS), the effects of hazardous heat exposure resulted in an average of 35 fatalities per year and an average of 2,700 cases with multiple days away from work between 2015 and 2019. The actual numbers may be higher, because BLS indicates that heat-related fatalities may be underreported and improperly diagnosed due to failures to document when exposures to heat caused or contributed to “official” causes of death, such as heart attacks.

Advanced Notice of Proposed Rulemaking (ANPRM)

OSHA published an ANPRM in the Federal Register on October 27, 2021. OSHA’s stated purpose in starting to work on a heat exposure standard, according to the landing page for the ANPRM, is to “more clearly set forth employer obligations and the measures necessary to more effectively protect employees from hazardous heat.” OSHA also produced a fact sheet on the ANPRM, as shown below.

For the benefit of anyone unfamiliar with the way OSHA uses ANPRMs, let’s discuss that. An ANPRM is basically an announcement that OSHA has serious plans to undertake a rulemaking, and is looking for technical expertise and stakeholder feedback that can help guide them in that process. In this instance, OSHA stated they were specifically seeking feedback on the scope of a potential standard, heat stress thresholds for workers across various industries, heat exposure monitoring, and the types of controls employers should use.

Another topic that OSHA sought stakeholder feedback on is heat acclimatization planning. The term acclimatization refers to an employee’s build-up of resistance to heat exposure over time. There is a growing body of research and established best practices on heat acclimatization, including guidance published by Centers for Disease Control and Prevention (CDC). These existing guidelines have implications about how employers might use heat acclimatization as part of their plans to protect workers from harmful heat exposures. For example, because acclimatization builds over time, employers should not assign a new employee who hasn’t yet built up heat resistance to work a long shift in a hot environment. We’ll see that during the recent public hearing, stakeholders did provide feedback to OSHA about key potential considerations for using acclimatization.

The public comment period for the ANPRM closed on January 26, 2022. Of course, should OSHA issue a Notice of Proposed Rulemaking (NPRM) on a heat exposure standard, a new and separate public comment period would then begin.

National Emphasis Program (NEP)

OSHA demonstrated that it was keeping the goal of protecting workers from heat exposures top of mind by rolling out a new NEP on “Outdoor and Indoor Heat-Related Hazards” on April 8, 2022. The NEP lays out OSHA’s inspection and enforcement priorities to support reduction of occupational illnesses and fatalities from heat exposure.

Let’s take a high-level overview of the NEP.

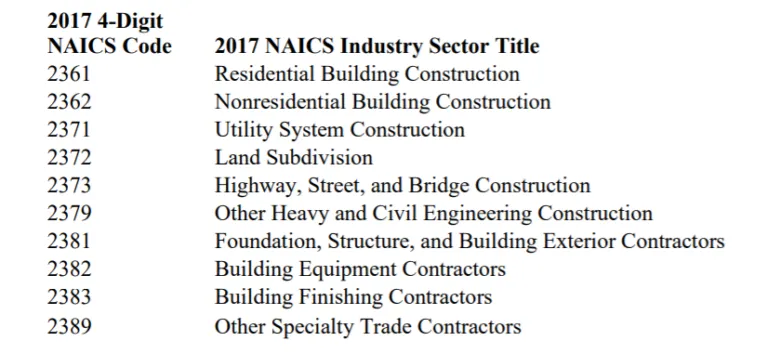

Site Selection: OSHA’s NEP contains an Appendix A of “Target Industries for the NEP” that lists the industry sectors, represented by North American Industrial Classification (NAIC) codes, that they’ll be focusing upon for inspections purposes.

How did OSHA decide which NAIC codes to include? According to the NEP, inclusion of an NAIC in Appendix A results from:

1) High numbers or high incidence rates of heat related illnesses from the Bureau

of Labor Statistics (BLS) data;

2) Elevated number of days away from work (BLS) or high numbers of severe cases of heat-related illnesses, as indicated by death or hospitalization, from OSHA severe injury reports made by employers; or

3) the highest number of heat-related general duty clause 5(a)(1) violations and HALs over a 5-year period (1/1/2017 thru 12/31/2021), or the highest number of OSHA heat inspections since 2017.

Not surprisingly, Appendix A includes a number of subsectors of the construction industry, as shown in the image below.

Appendix A also includes subsectors as diverse as restaurants, bakeries, facilities support services, automobile dealers, farming, chemical manufacturing, vehicle manufacturing, and wholesaling of various goods. Consult Appendix A for the full list.

Timing of Inspections: The NEP states that programmed inspections will occur on any day that the National Weather Service (NWS) has announced a heat warning or advisory for the local area. Appendix G of the NEP lists the types of NWS weather alerts that employers should know, both because they’re important for the protection of their employees, and because OSHA is more likely to conduct inspections on those days. Appendix G works together with Appendix A discussed above, because on days that the NWS issues an alert listed in Appendix G, they will conduct inspections of facilities in the affected area that have NAIC codes listed in Appendix A.

Focus of Heat-Related Inspections: According to the NEP, OSHA’s compliance safety and health officers (CSHOs) conducting a site inspection shall open or refer a heat-related inspection for any hazardous heat conditions observed, or recorded by the employee in the OSHA 300 logs or 301 Incident Reports they’re required to maintain under the Recordkeeping Standard. CSHOs will also open a case if an employee brings a heat-related hazard(s) such as lack of access to rest or shade, lack of acclimatization, and lack of proper training about heat hazards, to their attention during an inspection.

The NEP is currently in effect and applies “OSHA-wide,”(everywhere that federal OSHA has jurisdiction). States that have federally approved state OSHA plans are not required to adopt the NEP, but if they do so, they must adopt provisions at least as stringent as the federal NEP.

OSHA’s Public Hearing on Heat Exposure

OSHA held its public hearing on May 3, 2022. There was much public interest in the hearing, with over 3,000 registrants, which forced OSHA to expand access through YouTube livestreaming in addition to the original Zoom virtual meeting.

The hearing extended over a significant part of the day, and featured presentations by OSHA in addition to multiple 3-minute statements by stakeholders. Let’s review some of the major topics discussed during the hearing.

OSHA’s Summary of Recent and Planned Heat Initiatives

In a slide presentation, OSHA representatives reviewed OSHA’s recent actions on heat exposure, and discussed plans for the near future.

OSHA representative Inane Mintz stated that OSHA launched its heat campaign in 2011, modelling it on the California OSHA (Cal/OSHA campaign). Mintz said that OSHA revised its existing campaign material in 2021, including a workplace poster, expanding the focus to address both indoor and outdoor exposures. OSHA also developed a pamphlet for workers based on the information in the poster and published infographics in both English and Spanish.

Following Mintz’s discussion, OSHA representative Pamela Barclay discussed some of OSHA’s 2022 plans, which include updating the agency’s Heat Exposure landing page and increasing awareness of the dangers of heat exposure via an electronic newsletter.

Mintz also stated that OSHA will be doing additional campaigning around its current video “Remembering Tim Barber.” Barber was a 35-year old construction worker who died in July 2020 from heat-related illness on only his second day on the job. The video, which talks about the role that lack of time for acclimatization played in Barber’s very preventable death, includes very emotional testimony from Barber’s father. You can watch the video here. It’s highly recommended viewing that very effectively puts a human face on this issue, and highlights the importance of employer responsibilities in preventing heat-related illnesses.

In a separate presentation, OSHA representative Christina Morgan described OSHA’s current Compliance Assistance activities related to heat exposure. Morgan stated that Compliance Assistance Specialists would be promoting best heat illness practices from participants in the Voluntary Protection Program (VPP), and labor liaisons based out of OSHA’s ten regional offices would be working with laborers and their representatives to identify heat exposure issues and provide guidance on heat illness prevention plans.

Finally, OSHA representative Jennifer Kim provided an overview of the current heat exposure NEP discussed previously. Kim stated that during site visits conducted under the NEP, CSHOS will interview employees regarding relevant details about heat exposure in the workplace, such as previous incidents of heat-related illnesses, and whether they’re aware if their employer has established a plan to reduce the number of heat-related illnesses. Kim also reminded attendees that the current maximum OSHA penalty for a “serious” violation is $14,502 per violation. On a more optimistic note, Kim stated that National Institute of Occupational Safety and Health (NIOSH) has made a heat safety tool app available, which provides employers with helpful information such as real-time and location-specific heat index and hourly forecasts, and heat safety recommendations from OSHA and NIOSH.

Stakeholder Feedback on OSHA’s Planned Heat Standard

Although not all of the stakeholders OSHA listed as participants based on their submitted notices actually attended the hearing, many different speakers shared their thoughts and concerns based on their specific perspectives. Participants includes representatives from industry, from labor organizations and labor rights advocacy groups, and from safety organizations such as National Safety Council (NSC), all of whom provided thoughts on OSHA’s plan to develop a heat exposure standard.

We discuss main themes of stakeholder feedback below.

Appropriate Industry Targeting: Interestingly, no participants expressed the view that an OSHA heat exposure standard was unnecessary, which shows there is a very wide consensus supporting OSHA regulatory action in this area. Still, several commentators stated that any future OSHA standard would need to be targeted at the specific industries where heat exposures are more likely, based on research of heat-related illness incidence rates.

Protection of the Most Vulnerable Worker Populations: Several representatives of labor groups expressed concern that OSHA prioritize protection of the most vulnerable populations of workers. For example, several participants mentioned the higher heat exposure risks of farm workers, who often lack access to air-conditioned break areas, shade, or water stations. One labor advocate also mentioned the example of a 48-year old Latina farmworker who’d developed sunspots on her skin, and who’d brought attention to the problem that many Latino workers “were getting sick” because employers exploited their economic vulnerability and didn’t account for language differences when providing training. Another stakeholder mentioned the added hazards of heat exposure for pregnant women, who are more susceptible to heat-related illnesses.

Heat Acclimatization: Stakeholders brought up the importance of heat acclimatization, and of ensuring that any future OSHA standard stress the need for employers to include heat acclimatization policies in their heat illness reduction plans. Some commentators pointed out the connection of this issue with protection of vulnerable worker populations. For example, contracted and temporary workers may not work in the same place long enough to develop acclimatization, or may lose their acclimatization when shifted between worksites.

Occupational Exposure Limit (OEL): There was broad consensus that any future OSHA heat standard should be “performance based,” meaning based on outcomes like reduction of workplace heat illnesses rather than focused on establishing very specific means of achieving those aims. That said, several commentators also stated that an OSHA heat standard would need to have one or more OELs, such as a permissible exposure limit. Stakeholders suggested that possible OELs could include the heat index, or other such science-based exposure criterion.

Flexibility: Several participants made a congruent point with the perceived need for a “performance based” standard, emphasizing that OSHA should not delineate employer responsibilities too sharply, because that would risk leaving little room for employers to address the unique circumstances and heat hazards in their workplaces. Participants stressed that ranges in job tasks, workforce characteristics and local weather conditions (including factors such as humidity) make a “one size fits all” approach unlikely to succeed.

Major Takeaways from the Public Hearing

We covered a great deal in this post, and we encourage you to refer to the specific details discussed as often as you’d like. But if you’re just looking for some key takeaways, here are a few to remember:

OSHA is taking heat-related illnesses very seriously. While OSHA began talking about prevention of heat-related illnesses in a general way over a decade ago, the pace and potential impact of their efforts has significantly accelerated since last year. The ANPRM, the NEP, and the recent public hearing have all occurred during the past 7 months, and OSHA is clearly intent on moving forward with a rulemaking to protect both indoor and outdoor workers from heat exposures. Additionally, the much larger than anticipated registration numbers for the hearing show there is substantial public and industry interest in this initiative, and the comments from stakeholders demonstrate a broad consensus that a standard is needed.

OSHA inspectors will be looking at occupational injury and illness records. OSHA’s NEP states that CSHOs will be reviewing 300 and 301 forms as part of their site inspections. That means that compliance with the Recordkeeping Standard, and good incident management practices more generally, are very important parts of any effective heat illness prevention strategy.

OSHA will want to know what you’re doing to prevent heat-related injuries. The NEP states that OSHA will open investigations based on information potentially supplied by employees during inspections, and OSHA representatives during the hearing said that CSHOs will be asking if the employer has implemented a heat illness prevention plan. While we don’t yet have an OSHA proposed rule and so don’t know what specific employer requirements it will include, inspections are a common aspect of many safety programs, whether required by regulations or not. Regular inspections of worksites to ensure that water stations are stocked and PPE is available can go a long way toward reducing heat-related hazards.

Let VelocityEHS Help!

Getting prepared for OSHA’s planned rulemaking on occupational heat exposures involves many of the same safety management tasks you’re already doing. You just need the flexibility to adapt them, and the ability to make them easy enough to do consistently. Our Safety solution, part of the VelocityEHS Accelerate® Platform, allows you to develop site-specific checklists to confirm that supplies and PPE are on hand, and to use them in the field from a mobile device. You’ll also get the incident management control you need to document and follow up on heat illness cases, and to complete and access your OSHA recordkeeping forms.

As always, please feel free to contact us anytime to learn more about how we can help your business become safer and more sustainable.