By Greg Duncan, MELP, ASP, Sr. EHS & ESG Content Manager

The US Department of Labor (DOL) has just published the OSHA 2023 Semiannual Regulatory Agenda, detailing the Agency’s most up-to-date regulatory actions and providing employers with valuable insights into upcoming OSHA regulatory activities that are likely to impact their organizations. For EHS professionals, it can feel like a full-time job just keeping up with existing OSHA requirements affecting your business, not to mention the seemingly endless stream of new and changing regulations. Here, we’ll look at the OSHA 2023 Semiannual Regulatory Agenda to discuss what’s new and analyze key OSHA regulatory actions to help you prepare for how they could affect your organization.

Understanding the OSHA 2023 Semiannual Regulatory Agenda

The OSHA 2023 Semiannual Regulatory Agenda is broken into three primary categories: Pre-Rule Stage, Proposed Rule Stage, and Final Rule Stage. Understanding the rulemaking process and the timeline for each of these stages offers employers some important clues about when these regulations are likely to come into force.

Pre-Rule Stage

These are regulatory actions which have moved from OSHA’s long-term regulatory actions plan into the rulemaking process. Often, pre-rule stage regulatory actions may remain in the pre-rule stage for years, having to go through requests for information (RFI), stakeholder comment and consultation periods, Small Business Regulatory Enforcement Fairness Act (SBREFA) review and approval, and potentially other rulemaking hurdles before they can be considered for proposed rulemaking, if at all. In some instances, such as OSHA’s long-proposed updates to its Lockout/Tagout (LOTO) Standard, regulatory actions were moved from the pre-rule stage back into the long-term regulatory actions plan.

Proposed Rule Stage

These are regulatory actions which have successfully passed regulatory reviews in the pre-rule stage and for which a Notice of Proposed Rulemaking (NPRM) has been published by OSHA. Once an NPRM has been issued, the proposed rule must go through a mandatory public comment period during which affected employers and other stakeholders may suggest changes to the rule, contest specific provisions within the NPRM, or provide any other feedback whether positive or negative. Public comment periods must be 60 days at a minimum (although they may be shortened in certain circumstances) and are often extended to allow for ample stakeholder feedback. Once the public comment period is closed and OSHA incorporates those comments into a final rule, the rule must pass some final reviews and approvals including a Federalism and Unfunded Mandates analysis, impacts on state, local and tribal governments, and review by the US Office of Management & Budget (OMB) to evaluate the economic impact to industry of the proposed rule.

Final Rule Stage

These are regulatory actions which have successfully passed full review during the proposed rule stage and may now be published in the US Federal Register. Final rules will include an effective date at which point they become law. Often, especially in instances where final rule requirements for employers are more complex, the Final Rule will specify a phased compliance timeline that will prescribe specific milestones for meeting individual provisions or aspects of the Rule, such as with the proposed updates to OSHA’s Hazard Communication Standard (HazCom) that we’ll discuss shortly.

Let’s look at some of the more notable regulatory actions in each of the three stages of the rulemaking process to understand what actions OSHA is currently taking, what may be coming in the future, and how to prepare your organization for changing requirements.

For a more detailed overview of the OSHA Rulemaking Process, click here.

Upcoming OSHA Final Rulemaking Actions

There are two particularly notable final rulemaking actions announced in the OSHA 2023 Semiannual Regulatory Agenda: The long-awaited updates to OSHA’s Hazard Communication Standard (HazCom) and revisions to OSHA’s workplace injury and illness recordkeeping requirements under the Improve Tracking of Workplace Injuries and Illnesses Final Rule.

OSHA Hazard Communication Standard (HazCom)

OSHA’s Hazard Communication Standard (HazCom) is a good place to dive into OSHA’s Semiannual Regulatory Agenda since it’s arguably the most impactful and far-reaching of the regulatory changes we’ll be discussing.

On February 16, 2021, OSHA published a long-awaited notice of proposed rulemaking (NPRM) to update the HazCom Standard by aligning it with Revision 7 of the UN’s Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The proposed changes would have impacts throughout the chemical supply chain, especially on manufacturers of affected chemical products.

The NPRM proposes major updates, including revised classifications for flammable gases, aerosols and desensitized explosives, revised requirements for “small” and “very small” shipped containers, revised shipping requirements for “bulk shipments,” and requirements for classification of hazards under “normal conditions of use,” including those resulting from chemical reactions and physical changes. The NPRM would require manufacturers of substances to comply with these new requirements within one year of the effective date of the eventual final rule, while manufacturers of mixtures would have two years from that final rule effective date.

For a deeper dive into the provisions of the HazCom NPRM, check out our eBook, A Deeper Look at OSHA’s Proposed GHS Revision 7 Update to the HazCom Standard.

The OSHA 2023 Semiannual Regulatory Agenda states the HazCom NPRM is in the final rule stage, although it should be noted that the Rule has been in the final rule stage at least since publishing its 2022 Spring Regulatory Agenda. OSHA currently lists the target publication date of the HazCom Final Rule as June 2023, and that has not been updated since earlier this year. It remains to be seen when the Final Rule will be published, many are anticipating OSHA to release the Final Rule before the end of 2023 at which point, the compliance clock will start. We’ll need to wait for that final rule to see if OSHA changes the phased-in compliance timeline from the NPRM, because many industry representatives who participated in a 2021 public hearing stated that the timeline for manufacturers of both substances and mixtures wasn’t long enough. One thing we can be sure of is that big changes are coming, and companies throughout the chemical supply chain will need to prepare.

OSHA’s Recordkeeping Rule

On July 21, 2023, OSHA published its long-awaited final rule updating electronic injury and illness reporting requirements in its Recordkeeping Standard. Many stakeholders had been carefully following OSHA’s actions on this rulemaking because of its wide-reaching impacts, including the expansion of electronic reporting obligations for many establishments. The final rule becomes effective on January 1, 2024 and the first reports under revised requirements are due March 2, 2024 which means that businesses will need to quickly prepare to meet updated requirements.

The previously published final rule issued back in May 2016 revised OSHA’s Recordkeeping Standard to require some establishments, which were already subject to injury and illness recordkeeping requirements, to electronically transmit injury and illness data from Form 300A directly to OSHA. OSHA created the Injury Tracking Application (ITA) as a web-based platform for employers to use when transmitting their data.

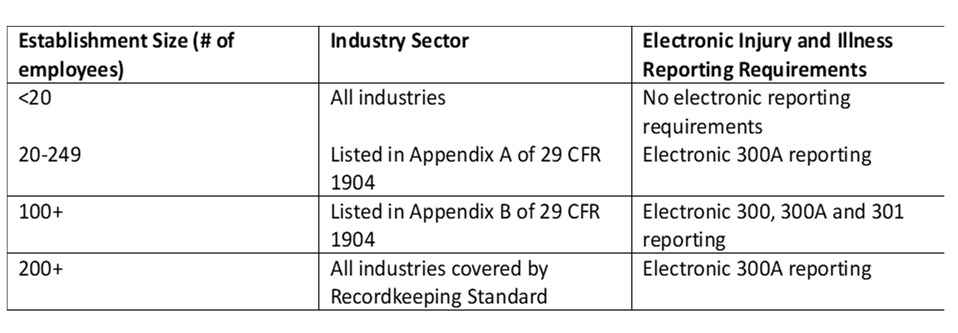

The 2023 final rule makes significant changes to electronic reporting requirements for many establishments covered under OSHA’s Recordkeeping Standard. It includes changes to the sizes of establishments (by employee number) who are required to submit injury and illness data to the ITA and adds information reporting requirements to include OSHA 300 and 301 form data depending on both establishment size and industry sector.

The table below summarizes the different categories of injury and illness reporting requirements under the final rule:

For a full, detailed analysis of the new OSHA electronic reporting final rule, visit the VelocityEHS Blog.

OSHA Proposed Rulemaking Actions

Though it will likely be several months, potentially years before OSHA’s proposed rule changes may be finalized and enforced, employers should have these proposed actions on their radar. Not only because it can take significant time to implement the systems, processes, and personnel necessary for compliance, but also because these proposed rulemaking actions are indicative of OSHA’s current and near-term enforcement initiatives and priorities. In other words, even though these proposed actions are not yet law, OSHA enforcement is likely focused on the workplace hazards at the heart of these proposed actions.

Infectious Diseases

In 2010, OSHA has been in the process of developing an Infectious Diseases Standard to address perceived gaps in workplace protections established under the Bloodborne Pathogens Standard. Healthcare workers and workers in related occupations, or who are exposed in other high-risk environments, are at increased risk of contracting TB, SARS, Methicillin-Resistant Staphylococcus Aureus (MRSA), COVID-19, and other infectious diseases that can be transmitted through a variety of exposure routes.

Hazard controls and other requirements that may be prescribed by a potential Infectious Diseases Standard would likely include formal infection control (IC) programs, hazard and risk assessment, respiratory PPE requirements, vaccination requirements, recordkeeping, isolation precautions and infection prevention engineering controls that may include the use of airborne infection isolation rooms (AIIRs).

Workplaces where such control measures might be necessary include health care, emergency response, prisons, homeless shelters, drug treatment program facilities, and other occupational settings where employees can be at increased risk of exposure to infectious disease hazards. A standard could also apply to laboratory facilities where pathogenic materials are handled including pathologists and coroners’ offices, medical examiners, and mortuaries.

An NPRM of the Infectious Diseases Standard has not yet been published, but OSHA’s rulemaking process for the Standard completed the SBREFA review in 2014, and a NPRM is currently targeted for March 2024.

Occupational Exposure to Crystalline Silica: Revisions to Medical Surveillance Provisions for Medical Removal Protection

On March 25, 2016, OSHA published a final rule on Occupational Exposure to Respirable Crystalline Silica (81 FR 16286). OSHA issued two separate standards: one for construction and one for general industry and maritime. The 2016 standards established a new exposure action level (AL) of 25 µg/m3 and reduced the silica PEL from 100 to 50 µg/m3— both calculated as 8-hour time-weighted averages (TWAs). The standards also include requirements for installing exposure controls, implementing medical surveillance programs to monitor workers’ health and exposure to RCS, and maintaining a written exposure control plan.

At the time, neither standard included a provision for medical removal protection for exposed workers. Shortly after implementation of the Silica final rule, both industry and labor organizations petitioned OSHA for review of the rule, and subsequent review by the U.S. Court of Appeals for the District of Columbia Circuit concluded that OSHA failed to adequately explain its decision to omit medical removal protections from the rule. The Court handed the rule back to OSHA for further consideration of the issue.

Some stakeholders weren’t satisfied with the level of protection provided by the 2016 final rules, specifically taking issue that the rules contained medical surveillance provisions but not medical removal provisions. Many OSHA standards regulating workplace exposure to hazardous chemicals have medical removal provisions that require employers to monitor certain exposure indicators such as airborne concentrations of chemicals or bloodborne concentrations (as in the case of lead exposure) and remove the employee from the source of exposure once specified maximum levels are reached.

OSHA’s planned rulemaking would significantly impact affected industries, which include many cement and asphalt manufacturing and construction facilities. We should also note the significant link to OSHA’s Recordkeeping Standard here because medical removal cases count as recordable injuries—either as “days away from work” or “restricted duty” depending on whether the employer complies by completely keeping the employee off work or by just changing their work duties to reduce silica exposure. Employers subject to the silica rules will need to be sure they have thorough workplace inspection and industrial hygiene (IH) medical surveillance programs in place, but an efficient incident management system to enable prompt recording of medical removal cases.

OSHA’s Semiannual Regulatory Agenda indicates that Occupational Exposure to Crystalline Silica: Revisions to Medical Surveillance Provisions for Medical Removal Protection rule remains in the proposed rule stage and indicates a target date of January 2024 for publication of an NPRM.

Welding in Construction Confined Spaces

OSHA is proposing to amend the Welding and Cutting Standard in construction to clarify the definition of “confined space” that applies to welding activities in construction. OSHA published its current final rule for Confined Spaces in Construction in 2015, adding a new subpart to provide protections to employees working in confined spaces in construction. This new subpart replaced OSHA’s singular training requirement for confined space work with a more comprehensive standard that prescribes a permit to work (PTW) program designed to protect employees from exposure to the hazards associated with work in confined spaces, including atmospheric and physical hazards.

Subsequent OSHA guidance on the final rule also discusses how the Welding and Cutting Standard in Construction works in conjunction with OSHA’s Confined Spaces Standard to apply and enforce their respective requirements. Although OSHA’s Confined Spaces Standard states that it encompasses welding activities, OSHA’s Welding Standard itself does not expressly define what a “confined space” is.

OSHA’s proposed rulemaking is to eliminate any perceived ambiguity about the definition of confined space that applies to welding activities in construction. An NPRM of an updated Welding in Construction Confined Spaces final rule is currently scheduled to be published in August 2023, and could have significant impacts to construction workers and employers who perform welding, cutting, and brazing activities under the proposed definition of “confined spaces” – a definition that will likely align with the definition laid out in OSHA’s Confined Spaces Standard.

OSHA Pre-Rule Stage Actions

The OSHA 2023 Semiannual Regulatory Agenda also names a handful of regulatory actions at the pre-rule stage which, though they may be years from potential proposed rulemaking, offer significant clues into what areas of workplace health and safety OSHA will likely be focused on through its near-term enforcement policies and initiatives.

Heat Illness Prevention in Outdoor and Indoor Work Settings

This is one pre-rule action on the OSHA 2023 Semiannual Regulatory Agenda that has been a particular point of focus in recent years, and signs suggest that OSHA could be taking aggressive action on it in the near future.

Exposure to extreme temperatures is a major cause of workplace injury and illness in the US. In 2021, 43 workplace fatalities were attributed to extreme temperatures. Numbers of non-fatal occupational illnesses due to exposure to extreme heat are less clear, as worker heat-related illnesses which do not require or receive medical treatment do not need to be recorded under OSHA Recordkeeping requirements. However, US Bureau of Labor Statistics (BLS) data estimates that heat stress has resulted in more than 70,000 serious worker injuries and illnesses between 1992 and 2017. Workplace heat hazards remain a significant concern for workers, employers, and regulators alike, and are an increasing concern as summer temperatures across the country continue to break records.

Currently, there is no specific OSHA standard addressing occupational heat-related illnesses. OSHA has used its General Duty Clause to cite employers where heat hazards and heat-related illnesses are identified, and OSHA has published a wealth of resources for workers and employers to help prevent heat-related illnesses but has stopped short of developing and enforcing a heat illness prevention standard…until recently.

In late 2021, OSHA published an Advance Notice of Proposed Rulemaking (ANPRM) for Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings in the Federal Register. The ANPRM marks the beginning of a formal rulemaking process to consider a heat-specific workplace standard that would codify employers’ obligations and prescribe the hazard controls necessary to protect workers from heat hazards. OSHA intends to initiate SBREFA review in August of 2023, but barring a highly expedited rulemaking to address heat hazards, it could be several years before OSHA publishes a final rule.

The lack of a formal heat illness prevention standard should not suggest that OSHA isn’t citing employers for workplace heat hazards under the General Duty Clause. In April 2022, OSHA rolled out a new National Enforcement Program (NEP) on “Outdoor and Indoor Heat-Related Hazards.” The NEP lays out OSHA’s inspection and enforcement priorities to support reduction of occupational illnesses and fatalities from heat exposure.

OSHA’s NEP contains an Appendix A of “Target Industries for the NEP” that lists the North American Industrial Classification System (NAICS) sectors that they’ll be focusing on for targeted inspection activities. According to the NEP, inclusion of an NAICS code in Appendix A is based on factors including high numbers or high incidence rates of heat related illnesses from the Bureau of Labor Statistics (BLS) data, especially severe cases, and numbers of heat-related general duty clause 5(a)(1) violations.

The NEP states that programmed inspections will occur on days that the National Weather Service (NWS) has announced heat warnings or advisories for the local area. According to the NEP, OSHA’s compliance safety and health officers (CSHOs) conducting a site inspection will open or refer a heat-related case incident for any hazardous heat conditions observed or recorded by the employer in the OSHA 300 logs or 301 reports they’re required to maintain under the Recordkeeping Standard. CSHOs will also open a case if an employee reports heat-related hazard(s) such as lack of access to rest or shade, lack of acclimatization, and lack of proper training about heat hazards during an inspection.

The NEP is currently in effect and applies “OSHA-wide” (everywhere under federal OSHA’s jurisdiction). States with federally approved state OSHA plans are not required to adopt the NEP, but if they do so, they must adopt provisions at least as stringent as the federal NEP.

Key Takeaways from the OSHA 2023 Semiannual Regulatory Agenda

The OSHA 2023 Semiannual Regulatory Agenda points to numerous regulatory and enforcement activities that could impact employers in a wide range of industry sectors. It’s a lot to absorb, so let’s slow down for a moment and review major takeaways.

Sharpen your inspection programs

Inspections are one of the most common tasks employers need to perform to verify compliance with OSHA standards. There is always a need to confirm that workers have received appropriate training, that hazards have been identified, that prescribed hazard controls are in place, and that requirements have been met. All of this means that you’ll need an efficient inspections program to verify compliance with evolving regulatory requirements. The VelocityEHS Safety Solution can help by making it easy to develop tailored, site-specific inspection checklists you and your workforce can easily and rapidly deploy from anywhere.

Incident management

OSHA’s final rule to update electronic reporting requirement requires many establishments already submitting 300A data to begin electronically reporting data from Forms 300 and 301 as well. The Safety Solution can help streamline workplace injury and illness reporting by simplifying and centralizing recordkeeping and automatically generating the required OSHA forms. OSHA’s planned inclusion of medical removal provisions in the updated RCS standard provides additional incentive to improve recordkeeping practices, since medical removable cases count as recordable injuries.

SDS/Chemical management

OSHA’s HazCom Standard updates are on the horizon and when the final rule is published, they’ll kick off a compliance scramble that will impact businesses throughout the chemical supply chain. Chemical manufacturers of aerosols, flammable gases, and desensitized explosives will need to re-classify many products, re-author SDSs, and produce new shipped container labels reflecting the new classifications and revised label elements such as hazard statements and pictograms. Downstream users of chemicals will need to prepare for an influx of revised SDS documents and labels and train their workers on all updated hazard information. The Safety Solution makes compliance easy by helping you maintain an up-to-date SDS library that you and your employees can access from anywhere via the cloud, and printing accurate secondary/workplace container labels aligned with the updated SDSs.

Better data for better decision-making

To stay on top of a shifting regulatory landscape, you’ll need to stay agile. That means ready access to key safety data so you can easily track progress, shift your approach when needed, and make more informed decisions to drive continuous improvement. With the , you’ll have access to customizable dashboards and real-time performance reports with automated report sharing features so you and your most important team members will always have access to the information you most need, when you need it.

Be sure to follow us on LinkedIn so you can always get the latest updates on the worlds of EHS & ESG.

Let VelocityEHS Help!

It’s easier to stay agile if your tools are agile, too. The Safety Solution, part of the VelocityEHS Accelerate® Platform, gives you the support you need to keep up with your most important safety tasks and be better prepared for OSHA’s next enforcement or regulatory actions.

Check out the Safety Solution page to learn more about how we can help you be safer and more sustainable, or to request a demo.