Table of Contents

- What is the Background of OSHA’s New Heat Injury and Illness Proposed Rule?

- OSHA’s 2021 Advanced Notice of Proposed Rulemaking (ANPRM)

- OSHA’s Heat National Emphasis Program (NEP)

- OSHA’s 2022 Public Hearing

- Which Workplaces Would OSHA’s NPRM Apply To?

- What Would OSHA’s New Heat Injury and Illness Proposed Rule Require?

- Heat Injury and Illness Prevention Plan (HIIPP)

- General Employer Responsibilities

- Control Measures at Initial Heat Trigger

- Control Measures at the High Heat Trigger

- Summary of Employer Responsibilities in OSHA's New Heat Injury and Illness Proposed Rule

- What Happens Next?

- Let VelocityEHS Help!

By Phil Molé, MPH

After years of preparatory work, OSHA recently published a Notice of Proposed Rulemaking (NPRM) on heat injury and illness prevention that will affect many outdoor and indoor US worksites. Employers across different industries will need to understand the potential requirements in OSHA’s new heat injury and illness proposed rule and start planning changes to their workplace safety and risk management practices.

In what follows, you’ll get a break down of OSHA’s new heat injury and illness NPRM and learn key takeaways to prepare for the next steps.

What is the Background of OSHA’s New Heat Injury and Illness Proposed Rule?

It might be helpful to review some of the milestones on the road to OSHA’s new heat injury and illness prevention proposed rule.

OSHA’s 2021 Advanced Notice of Proposed Rulemaking (ANPRM)

OSHA has always had the authority to regulate hazards associated with indoor and outdoor heat exposure. Even in the absence of a specific regulation, they could issue violations to employers for unaddressed heat-related hazards under the General Duty Clause (GDC).

Even so, OSHA concluded that existing enforcement protocols were not sufficient to protect workers from exposure to indoor and outdoor heat hazards. As is often the case, OSHA was driven mostly by the injury and illness statistics. According to the U.S. Department of Labor’s Bureau of Labor Statistics (BLS), the effects of hazardous heat exposure resulted in an average of 35 fatalities per year and an average of 2,700 cases with multiple days away from work between 2015 and 2019. The actual numbers may be higher, because BLS indicates that heat-related fatalities may be underreported and improperly diagnosed due to failures to document when exposures to heat caused or contributed to “official” causes of death, such as heart attacks.

OSHA published an ANPRM in the Federal Register on October 27, 2021. For context, an ANPRM is a preparatory step in the rulemaking process to solicit feedback from experts and stakeholders that can lay a foundation for later steps. OSHA’s stated purpose in starting to work on a heat exposure standard, according to the landing page for the ANPRM, is to “more clearly set forth employer obligations and the measures necessary to more effectively protect employees from hazardous heat,” in light of the disturbing trends in heat related injury and illness numbers.

Another topic that OSHA sought stakeholder feedback on via the ANRPM is heat acclimatization planning. The term acclimatization refers to an employee’s build-up of resistance to heat exposure over time. There is a growing body of research and established best practices on heat acclimatization, including guidance published by Centers for Disease Control and Prevention (CDC). These existing guidelines have implications about how employers might use heat acclimatization as part of their plans to protect workers from harmful heat exposures. For example, because acclimatization takes time, employers should not assign a new employee who hasn’t yet built-up heat resistance to work a long shift in a hot environment.

OSHA’s Heat National Emphasis Program (NEP)

OSHA demonstrated that it was keeping the goal of protecting workers from heat exposures top of mind by rolling out a new NEP on “Outdoor and Indoor Heat-Related Hazards” on April 8, 2022. The NEP lays out OSHA’s inspection and enforcement priorities to support reduction of occupational illnesses and fatalities from heat exposure.

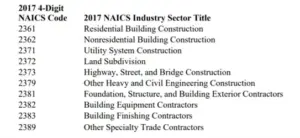

OSHA’s NEP contains an Appendix A of “Target Industries for the NEP” that lists the industry sectors, represented by North American Industrial Classification (NAIC) codes, that they’ll be focusing upon for inspections purposes.

How did OSHA decide which NAIC codes to include? According to the NEP, inclusion of an NAIC in Appendix A results from:

1) High numbers or high incidence rates of heat related illnesses from the Bureau of Labor Statistics (BLS) data;

2) Elevated number of days away from work (BLS) or high numbers of severe cases of heat-related illnesses, as indicated by death or hospitalization, from OSHA severe injury reports made by employers; or

3) the highest number of heat-related general duty clause 5(a)(1) violations and HALs over a 5-year period (1/1/2017 through 12/31/2021), or the highest number of OSHA heat inspections since 2017.

Not surprisingly, OSHA’s heat exposure NEP targets several subsectors of the construction industry, as seen in the image below.

The NEP is currently in effect and applies “OSHA-wide,” (everywhere that federal OSHA has jurisdiction). States that have federally approved state OSHA plans are not required to adopt the NEP, but if they do so, they must adopt provisions at least as stringent as the federal NEP.

OSHA’s 2022 Public Hearing

OSHA held a public hearing on May 3, 2022, to solicit stakeholder feedback on its efforts to develop a heat injury and illness standard, along with its other efforts to protect employees from heat exposure. There was much public interest in the hearing, with over 3,000 registrants, which forced OSHA to expand access through YouTube livestreaming in addition to the original Zoom virtual meeting. VelocityEHS virtually attended the hearing, which extended over a significant part of the day, and featured presentations by OSHA in addition to multiple 3-minute statements by stakeholders.

Stakeholders at the public hearing brought up the importance of heat acclimatization and ensuring that any future OSHA standard stress the need for employers to include heat acclimatization policies in their heat illness reduction plans. OSHA representatives also talked about acclimatization in the context of their heat safety campaign video “Remembering Tim Barber.” Barber was a 35-year-old construction worker who died in July 2020 from heat-related illness on only his second day on the job. The video, which talks about the role that lack of time for acclimatization played in Barber’s very preventable death, includes very emotional testimony from Barber’s father.

Some commentators pointed out the connection of this issue with protection of vulnerable worker populations. For example, contracted and temporary workers may not work in the same place long enough to develop acclimatization, or may lose their acclimatization when shifted between worksites.

Which Workplaces Would OSHA’s NPRM Apply To?

OSHA’s efforts to protect workers from heat exposure risks based on stakeholder feedback have resulted in development an NPRM. At the time of this writing, OSHA’s new heat injury and illness proposed rule is still not published in the Federal Register, which means we don’t yet know the deadline for submitting comments, but interested readers can review the full text of the NPRM here, as submitted to the Office of the Federal Register (OFR).

The proposed requirements in OSHA’s new heat injury and illness proposed rule would apply to almost all workplaces with outdoor and indoor operations in the general industry, construction, maritime, and agriculture sectors, if those workplaces are covered under the Occupational Safety and Health (OSH) Act. The NPRM does have some exclusions, such as:

- short duration employee exposures to heat;

- emergency response activities;

- work at indoor sites kept below 80°F;

- telework; and

- indoor sedentary work activities

According to a preliminary economic analysis OSHA conducted for the NPRM, some of the industries likely to be affected by the proposed requirements include:

- Agriculture, Forestry, and Fishing;

- Building Materials and Equipment Suppliers;

- Commercial Kitchens;

- Construction;

- Drycleaning and Commercial Laundries;

- Landscaping and Facilities Support;

- Maintenance and Repair;

- Manufacturing;

- Oil and Gas;

- Postal and Delivery Services;

- Recreation and Amusement;

- Sanitation and Waste Removal;

- Telecommunications;

- Temporary Help Services;

- Transportation;

- Utilities; and

- Warehousing

Alongside the economic analysis, OSHA also conducted an equity assessment of the potential impacts of the final rule and concluded that the provisions of the NPRM would “have a positive impact on underserved populations (e.g., low income and Hispanic workers) by providing workplace protections from extreme temperatures that have a disproportionate impact on occupations held by individuals from underserved communities.” This assessment shows that OSHA considered and incorporated stakeholder feedback during the 2022 public hearing about the priority to protect the most vulnerable worker populations.

OSHA considers the industries listed above to be “core” sectors in their economic analysis, meaning that they’re industries where “employees have the most exposure to heat-related hazards, such as through exposure to high outdoor temperatures, radiant heat sources, or insufficient temperature control or ventilation in indoor work settings.” You’ll also see that there’s some overlap between these sectors and those targeted by OSHA’s heat exposure NEP discussed earlier.

Still, remember that not seeing your industry sector on this bulleted list doesn’t mean the NPRM’s proposed requirements won’t apply to you. The proposed requirements will apply to you if you have significant indoor or outdoor heat exposure in your workplace, and you’ll have specific things to do under certain conditions, as you’ll now learn.

What Would OSHA’s New Heat Injury and Illness Proposed Rule Require?

In general, OSHA’s new heat injury and illness proposed rule sets out proposed requirements that OSHA intends to establish consistent employer obligations to protect employees from the hazards of heat exposure in both indoor and outdoor work environments.

Below, you’ll find a discussion of some of the major proposed requirements in the NPRM.

Heat Injury and Illness Prevention Plan (HIIPP)

Employers must develop a site-specific HIIPP describing workplace measures to evaluate and control heat hazards.

Note the “site-specific” part, because that’s important. An already existing, widely applicable regulation with similar “site specific” plan requirements is the HazCom Standard, which requires employers to develop and maintain a site-specific written plan describing workplace HazCom practices. Similarly, the intention expressed in the NPRM is for the HIIPP to include specific details such as:

- A comprehensive list of the types of work activities covered by the plan;

- All policies and procedures necessary to comply with the requirements of this standard;

- An identification of the heat metric (i.e., heat index or wet bulb globe temperature) the employer will monitor to comply with their obligations; and

- The identity of one or more heat safety coordinators designated by the employer to implement and monitor the HIIPP.

If any employees wear vapor-impermeable clothing at the worksite, the employer must evaluate heat hazards from the clothing and implement policies and procedures to protect employees from increased heat injuries and illness risks associated with the clothing and describe these policies and procedures in the HIIPP. The NPRM defines “vapor-impermeable clothing as “full-body clothing that significantly inhibits or completely prevents sweat produced by the body from evaporating into the outside air,” including encapsulating suits, various forms of chemical resistant suits, and other forms of nonbreathable PPE.

If the employer has more than 10 employees at the worksite, the plan would need to be in writing. The NPRM also specifically proposes that the employer must develop and implement the HIIPP with the participation of “non-managerial employees,” language that echoes established safety management best practices in standards like ISO 45001, the international standard for occupational health & safety (OH&S) management systems. The NPRM also states that the employer would need to review and evaluate the effectiveness of the HIIPP whenever a heat-related illness or injury occurs that results in death, days away from work, medical treatment beyond first aid, or loss of consciousness, making updates as needed. The employer would also need to review and update the plan at least annually.

Finally, OSHA’s new heat injury and illness proposed rule states that the employer must make the HIIPP available to all employees at the worksite and must be available “in a language each employee, supervisor, and heat safety coordinator understands.”

Identification of Heat Hazards

OSHA’s new heat injury and illness proposed rule would require employers at both indoor and outdoor work sites to identify heat hazards, as follows:

Employers at outdoor work sites would need to monitor heat conditions by tracking local heat index forecasts or measuring heat index or wet bulb globe temperature (WBGT). You can think of WBGT as a measurement of how heat “feels” to humans and incorporates all four major environmental heat factors: air temperature, humidity, radiant heat (from sunlight or sources such as furnaces), and air movement (wind or ventilation).

Employers at indoor work sites would need to identify work areas with the potential for hazardous heat exposure, develop and implement a monitoring plan, and seek employee input.

General Employer Responsibilities

OSHA’s new heat injury and illness proposed rule would establish the following general requirements for all employers:

- Take steps if an employee is experiencing signs and symptoms of a heat-related illness or a heat emergency and develop a heat emergency response plan.

- Provide initial and annual refresher training for supervisors, heat safety coordinators, and employees, and supplemental training after changes in exposure to heat hazards, policies and procedures, or the occurrence of a heat injury or illness.

- Have and maintain, for a minimum of six months, written or electronic records of indoor monitoring data.

- Ensure that all requirements are at no cost to employees.

Control Measures at Initial Heat Trigger

The NPRM proposes a two-tiered system of triggers that works something like the Action Level (AL) and Permissible Exposure Limit (PEL) do in existing exposure standards. That is, certain requirements kick in for the employer when the first (lower tier) exposure criteria are present, and additional requirements kick in at the higher tier.

In OSHA’s new heat injury and illness proposed rule, the “initial heat trigger” represents the lower exposure tier. The NPRM defines the initial heat trigger as a heat index of 80°F or a wet bulb globe temperature equal to the NIOSH Recommended Action Limit (RAL). When employers identify that worksite temperatures are at or above the initial heat trigger, they must provide their employees with the following provisions:

- cool drinking water;

- break areas with cooling measures;

- indoor work area controls;

- acclimatization protocols for new and returning unacclimatized employees;

- paid rest breaks if needed to prevent overheating; and

- regular and effective two-way communication.

Control Measures at the High Heat Trigger

The second exposure tier in the NPRM is the “high heat trigger,” defined as conditions at or above a heat index of 90°F or wet bulb globe temperature equal to the NIOSH Recommended Exposure Limit (REL).

When workplace conditions meet or exceed the high heat trigger, the employer must provide employees with the following:

- mandatory rest breaks of 15 minutes at least every two hours (unpaid meal break may count as a rest break);

- observation for signs and symptoms of heat-related illness;

- a hazard alert to remind employees of key parts of the HIIPP; and

- warning signs at indoor work areas with ambient temperatures that regularly exceed 120°F.

Summary of Employer Responsibilities in OSHA’s New Heat Injury and Illness Proposed Rule

The chart below summarizes all proposed requirements for employers in OSHA’s new heat injury and illness proposed rule.

| Provision | All Covered Employers | At or Above Initial Heat Trigger | At or Above High Heat Trigger |

| Identifying heat hazards | X | X | X |

| Heat illness and emergency response procedures | X | X | X |

| Heat Injury and Illness Prevention Plan (HIPP) | X | X | X |

| Recordkeeping | X | X | X |

| Drinking Water | X | X | |

| Break Area | X | X | |

| Indoor Work Area Controls | X | X | |

| Acclimatization plan for new or returning workers | X | X | |

| Rest breaks (if needed) | X | X | |

| Effective communication means with employees | X | X | |

| Rest breaks (minimum 15 minutes every 2 hours) | X | ||

| Supervisor or buddy system to observe | X | ||

| Hazard alert | X |

What Happens Next?

The public comment period for OSHA’s new heat injury and illness proposed rule is now open, and stakeholders may submit their feedback to OSHA via the docket. OSHA will then take some time to sort through the feedback en route to developing a final rule.

In the meantime, employers need to start preparing now. That means broadening your approach to safety and operational risk management to include exposure to heat hazards and prevention of heat injuries and illnesses. You’ll need to prepare inspection programs to confirm that indoor and outdoor work areas affected by the proposed requirements have necessary provisions in place, such as access to cool water, and functioning work areas controls like forced air cooling systems. It’s also important to reassess your incident management system to ensure it enables fast reporting of identified heat hazards, as well as any occupational injuries and illnesses that may occur, with the ability to quickly enter cases on OSHA Recordkeeping Forms.

Check this space often for additional updates about OSHA’s heat injury and illness NPRM as they happen!

Let VelocityEHS Help!

Preparing to meet the potential requirements in OSHA’s NPRM on occupational heat exposures involves many of the same safety management tasks you’re already doing. You just need the flexibility to adapt them, and the ability to make them easy enough to do consistently. Velocity’s Safety software allows you to develop site-specific checklists to confirm that supplies and PPE are on hand, and to use them in the field from a mobile device. You’ll also get the incident management control you need to document and follow up on heat illness cases, and to complete and access your OSHA recordkeeping forms.

Operational Risk software can also help you to improve your risk assessment acumen, with access to tools like hazard identification (HAZIDs), job safety analyses (JSAs), or risk bowties that can help you identify and control many kinds of hazards and risks, including those associated with heat exposure. You’ll also get enterprise-level visibility of hazards across your organization, and better ability to communicate risks and controls in place to all of your employees.

As always, please feel free to contact us anytime to learn more about how we can help your business become safer and more sustainable.