By Phil Molé, MPH

The Seveso III directive is one of the most important regulations in the EU, requiring operators of certain facilities storing dangerous chemicals to develop and implement emergency planning and response procedures. The directive officially covers approximately 12,000 EU establishments, and EU member states implement the directive through national legislation and enforce it through local regulatory agencies.

In what follows, you’ll learn about the background and purpose of Seveso III, as well as its requirements. You’ll also get some key takeaways to ensure compliance and improve your operational risk management practices.

What is the Background of Seveso III?

Accidents at chemical storage or processing facilities can have disastrous consequences. For example, one of the more significant accidents in the EU is the 2019 fire at a Lubrizol factory in Rouen. While it did not result in fatalities, it disrupted local business and destroyed harvests, leading to a 1,600-foot exclusion zone surrounding the facility. In January 2020, an accident involving two explosions at a Chemical Industries of Ethylene Oxide (IQOXE) facility in Tarragona, Catalonia, Spain killed three offsite people and injured seven. Because accidents like these can take a huge toll on human health and the environment, operators of chemical facilities need to be very proactive in their planning for emergency prevention and response. The Seveso III directive is intended to ensure exactly that.

Seveso III is the third version of the Seveso directive. It follows Seveso I (Directive 82/501/EC) and Seveso II (Directive 96/82/EC), taking its name from a 1976 industrial disaster near the Italian town of Seveso, located approximately 12 miles north of Milan. The accident occurred when plant management stopped a batch process before distillation could remove ethylene glycol built up from the reaction mixture. This resulted in a chain of events that led to the release of the highly toxic chemical 2,3,7,8-Tetrachlorodibenzodioxin (TCDD). Thousands of animals (mostly poultry and rabbits) near the facility died in the immediate aftermath of the accident, and officials ordered tens of thousands more to be killed to keep TCDD-infected meat from being sold to consumers. The most immediate health effect for humans was 193 cases of chloracne, a skin condition caused by exposure to chlorinated compounds. However, a 1991 follow-up study on the population exposed to TCDD from the Seveso disaster identified a higher incidence of health effects such as peripheral neuropathy, liver enzyme induction, and diabetes, as well as an elevated mortality rate from cardiovascular and respiratory diseases. It’s no wonder why a 2010 Time magazine article on the worst environmental disasters in history ranked the Seveso disaster at #8.

European countries developed the first version of the Seveso directive (Seveso I) after years of planning and stakeholder discussions about the best ways to prevent or mitigate accidents like the Seveso disaster. They enacted Seveso I in 1982. The EU reviewed and revised the directive in 1999, resulting in Seveso II, and the most recent set of updates resulting in Seveso III occurred in 2012.

Compared to Seveso II, Seveso III introduced several changes, including:

- An updated list of substances covered by Seveso to align with the CLP Regulation

- Revision of some definitions used in the directive

- Updated emergency planning provisions to require co-operation by designated authorities in tests of external emergency plans (for upper-tier facilities).

- Strengthened requirements for providing public information, including a duty for lower-tier establishments to provide public information.

- Broadened discussion and requirements of “domino effects” (discussed later).

The intention behind Seveso III is to require facility operators to take all necessary measures (both technical and organizational) to prevent accidents and limit their consequences. You’ll soon learn about the specific requirements within Seveso III intended to accomplish those objectives, but first, it’s important to understand a little context.

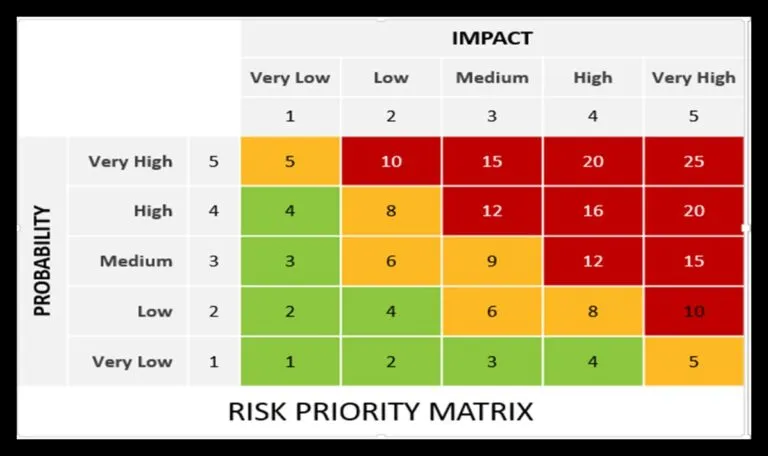

The creators of Seveso III clearly intended for it to facilitate better operational risk management with a goal of preventing accidents when possible and minimizing the impacts of accidents if they do happen. EHS managers measure risk as the product of the probability of a bad outcome, like an accident happening, and the severity of the outcome if it happens. The most common tool used to present risk measures is a risk matrix, shown in the image below:

Risks with the largest calculated products of probability and severity appear in the top right corner of the matrix, highlighted in bright, alarmist red. Risks with the lowest ranked scores wind up in the bottom left quadrant, highlighted in a much more calming green color. This visual organization of information makes the matrix intuitively understandable for everyone from EHS management to frontline workers.

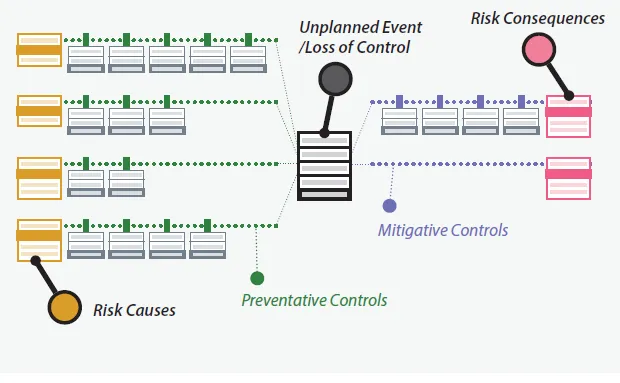

A popular risk management tool called the risk bowtie builds on this concept of risk by mapping out risk pathways. These show the relationship between risk causes, the unplanned/undesired event, and risk consequences, as shown in the image below.

If you look closely at the diagram above, you’ll see that the bowtie diagram also shows the placement of controls used to reduce levels of risk. Since risk management involves both the “before” and “after” aspects of an accident, so do the categories of controls, as shown in the table below.

| Type of Control | Active Before or After Accident? | Description |

| Preventive | Before | Controls intended to prevent, or at least reduce the probability, of a specific accident happening |

| Mitigative | After | Controls intended to reduce the severity of consequences after an accident happens |

| Detective | After | Controls designed to inform facility management that an accident has occurred, or in some cases that facility conditions are becoming increasingly hazardous and likely to lead to a major accident. |

Here’s an example to help you think about how you might use preventive, mitigative and detective controls in practice. Suppose you have a facility with large aboveground tanks (ASTs) of volatile liquids that tend to evolve vapors. One useful preventive control would be a safety valve, or pressure-relief valve, to vent some of the vapors before they can build up enough pressure to result in a tank rupture or explosion. What if the tank still ruptures? A bermed structure around the tanks designed to contain at least some of the overall liquid volume would be a mitigative control, because it would reduce the severity of the chemical spill. You can also use a detective control such as vapor monitors connected to an alarm system (consisting of both sound and visual warnings, like flashing lights) to let you know that harmful vapors are escaping, so you can immediately take measures to prevent a larger release and protect the safety of your employees.

As you read on about the requirements of Seveso III, try to see them as parts of an effective risk management strategy, as they’re intended to be. Compliance with Seveso III is not a foolproof method for preventing major accidents—in fact, the 2019 Lubrizol fire and the 2020 IQOXE explosion both occurred at facilities covered by Seveso III. Still, the requirements in Seveso III reduce the likelihood of accidents, and certainly enable smoother and safer response if accidents happen.

Which Facilities are Subject to Seveso III?

Now that you have some background in the history and intentions behind Seveso III, it’s time to understand its applicability. Not all EU facilities are subject to Seveso III, because the directive is intended to prevent major accidents at facilities storing and using large quantities of dangerous chemicals listed in Annex I of the directive.

Applicability of Seveso III depends on Substances that trigger coverage under Seveso III, which fall into two main categories:

1) Substances specifically named on list; and

2) Substances listed as part of a group of classifications under Classification, Labeling and Packaging (CLP)

The European Chemical Agency (ECHA) provides lists of these two groups of chemicals in the C + L Inventory, which is Annex I of Seveso III.

There are also two tiers of applicability to Seveso III, depending on quantities of chemicals stored at the facility. For reference, these thresholds (taken from Part 2 of Annex I) are shown in the table below.

| Column 1 | CAS number | Column 2 | Column 3 |

| Qualifying quantity (tonnes) for the application of | |||

| Dangerous substances | |||

| Lower-tier requirements | Upper-tier requirements | ||

| 1. Ammonium nitrate (see note 13) | — | 5 000 | 10 000 |

| 2. Ammonium nitrate (see note 14) | — | 1 250 | 5 000 |

| 3. Ammonium nitrate (see note 15) | — | 350 | 2 500 |

| 4. Ammonium nitrate (see note 16) | — | 10 | 50 |

| 5. Potassium nitrate (see note 17) | — | 5 000 | 10 000 |

| 6. Potassium nitrate (see note 18) | — | 1 250 | 5 000 |

| 7. Arsenic pentoxide, arsenic (V) acid and/or salts | 1303-28-2 | 1 | 2 |

| 8. Arsenic trioxide, arsenious (III) acid and/or salts | 1327-53-3 | 0,1 | |

| 9. Bromine | 7726-95-6 | 20 | 100 |

| 10. Chlorine | 7782-50-5 | 10 | 25 |

| 11. Nickel compounds in inhalable powder form: nickel monoxide, nickel dioxide, nickel sulphide, trinickel disulphide, dinickel trioxide | — | 1 | |

| 12. Ethyleneimine | 151-56-4 | 10 | 20 |

| 13. Fluorine | 7782-41-4 | 10 | 20 |

| 14. Formaldehyde (concentration ≥ 90 %) | 50-00-0 | 5 | 50 |

| 15. Hydrogen | 1333-74-0 | 5 | 50 |

| 16. Hydrogen chloride (liquefied gas) | 7647-01-0 | 25 | 250 |

| 17. Lead alkyls | — | 5 | 50 |

| 18. Liquefied flammable gases, Category 1 or 2 (including LPG) and natural gas (see note 19) | — | 50 | 200 |

| 19. Acetylene | 74-86-2 | 5 | 50 |

| 20. Ethylene oxide | 75-21-8 | 5 | 50 |

| 21. Propylene oxide | 75-56-9 | 5 | 50 |

| 22. Methanol | 67-56-1 | 500 | 5 000 |

| 23. 4, 4′-Methylene bis (2-chloraniline) and/or salts, in powder form | 101-14-4 | 0,01 | |

| 24. Methylisocyanate | 624-83-9 | 0,15 | |

| 25. Oxygen | 7782-44-7 | 200 | 2 000 |

| 26. 2,4 -Toluene diisocyanate | 584-84-9 | 10 | 100 |

| 2,6 -Toluene diisocyanate | 91-08-7 | ||

| 27. Carbonyl dichloride (phosgene) | 75-44-5 | 0,3 | 0,75 |

| 28. Arsine (arsenic trihydride) | 7784-42-1 | 0,2 | 1 |

| 29. Phosphine (phosphorus trihydride) | 7803-51-2 | 0,2 | 1 |

| 30. Sulphur dichloride | 10545-99-0 | 1 | |

| 31. Sulphur trioxide | 7446-11-9 | 15 | 75 |

| 32. Polychlorodibenzofurans and polychlorodibenzodioxins (including TCDD), calculated in TCDD equivalent (see note 20) | — | 0,001 | |

| 33. The following CARCINOGENS or the mixtures containing the following carcinogens at concentrations above 5 % by weight: 4-Aminobiphenyl and/or its salts, Benzotrichloride, Benzidine and/or salts, Bis (chloromethyl) ether, Chloromethyl methyl ether, 1,2-Dibromoethane, Diethyl sulphate, Dimethyl sulphate, Dimethylcarbamoyl chloride, 1,2-Dibromo-3-chloropropane, 1,2-Dimethylhydrazine, Dimethylnitrosamine, Hexamethylphosphoric triamide, Hydrazine, 2- Naphthylamine and/or salts, 4-Nitrodiphenyl, and 1,3 Propanesultone | — | 0,5 | 2 |

| 34. Petroleum products and alternative fuels (a) gasolines and naphthas, (b) kerosenes (including jet fuels), (c) gas oils (including diesel fuels, home heating oils and gas oil blending streams) (d) heavy fuel oils (e) alternative fuels serving the same purposes and with similar properties as regards flammability and environmental hazards as the products referred to in points (a) to (d) | — | 2 500 | 25 000 |

| 35. Anhydrous Ammonia | 7664-41-7 | 50 | 200 |

| 36. Boron trifluoride | 7637-07-2 | 5 | 20 |

| 37. Hydrogen sulphide | 7783-06-4 | 5 | 20 |

| 38. Piperidine | 110-89-4 | 50 | 200 |

| 39. Bis(2-dimethylaminoethyl) (methyl)amin | 3030-47-5 | 50 | 200 |

| 40. 3-(2-Ethylhexyloxy)propylamin | 5397-31-9 | 50 | 200 |

| 41. Mixtures (*1) of sodium hypochlorite classified as Aquatic Acute Category 1 [H400] containing less than 5 % active chlorine and not classified under any of the other hazard categories in Part 1 of Annex I. | 200 | 500 | |

| 42. Propylamine (see note 21) | 107-10-8 | 500 | 2 000 |

| 43. Tert-butyl acrylate (see note 21) | 1663-39-4 | 200 | 500 |

| 44. 2-Methyl-3-butenenitrile (see note 21) | 16529-56-9 | 500 | 2 000 |

| 45. Tetrahydro-3,5-dimethyl-1,3,5,-thiadiazine-2-thione (Dazomet) (see note 21) | 533-74-4 | 100 | 200 |

| 46. Methyl acrylate (see note 21) | 96-33-3 | 500 | 2 000 |

| 47. 3-Methylpyridine (see note 21) | 108-99-6 | 500 | 2 000 |

| 48. 1-Bromo-3-chloropropane (see note 21) | 109-70-6 | 500 | 2 000 |

Article 3 defines a lower-tier establishment as an establishment where dangerous substances are present in quantities equal to or above of the quantities listed in Column 2 of Part 1 or in Column 2 of Part 2 of Annex I, but less than the quantities listed in Column 3 of Part 1 or in Column 3 of Part 2 of Annex I.

An upper-tier establishment is an establishment where dangerous substances are present in quantities equal to or above the quantities listed in Column 3 of Part 1 or in Column 3 of Part 2 of Annex I, where applicable. Upper-tier establishments have higher risks due to the higher quantities of dangerous chemicals stored. Because of this, they have more stringent requirements to ensure they’re doing what’s necessary to prevent major accidents and minimize their consequences.

What Does Seveso III Require?

Here are some of the major requirements of Seveso III.

Notification Requirements

A facility operator who determines that their facility is subject to Seveso III must notify the competent authority about each accident that meets the major accident criteria published in Annex VI of Seveso III.

The major accident criteria are:

1. There are dangerous substances involved

Any fire or explosion or accidental discharge of a dangerous substance involving a quantity of at least 5 % of the qualifying quantity laid down in Column 3 of Part 1 or in Column 3 of Part 2 of Annex I.

2. People were injured, or damage to real estate occurred

Specifically, facility operators must report incidents involving any of the following:

| One or more fatalities; |

| Hospitalization of six (6) or more employees for at least 24 hours;One or more people outside of the establishment hospitalized for at least 24 hours; |

| Damage to residences outside the establishment due to the accident; |

| The evacuation or confinement of people for more than 500 person-hours (calculated as the number of people involved multiplied by the number of hours) |

| Interruption of drinking water, electricity, gas, or telephone services for more than 1000 person- hours |

If a facility operator determines that an incident met one or more of the reporting criteria listed above, they must complete and submit a report using the Major Accident Reporting System (eMARS) managed by the Major Accidents Bureau. The report submitted must include the following information:

- The name and/or trade name of the operator and the full address of the establishment concerned;

- The registered place of business of the operator, including the full site address;

- The name and position/title of the person in charge of the establishment;

- Information sufficient to identify the dangerous substances and category of substances involved or likely to be present;

- The quantity and physical form of the dangerous substance or substances involved in the incident;

- The activity or proposed activity of the installation or storage facility; and

- The immediate environment of the establishment, and factors likely to cause a major accident or to aggravate the consequences. This information must include (where available) details of neighboring establishments, areas and developments that could cause or increase the risk or consequences of a major accident and of domino effects.

Develop and Maintain a Major Accident Prevention Policy (MAPP)

Seveso III requires facility operators subject to the directive to develop and maintain a MAPP. The directive states that facility operators must design their MAPP to ensure “a high level of protection of human health and the environment.” Additionally, the MAPP must have a prioritized focus on the major-accident hazards that could occur at the facility and include the operator’s overall aims and principles of action, the role and responsibility of management, and the commitment to continuously improving the control of major-accident hazards.

Operators of lower-tier establishments may meet their obligation to implement the MAPP through other appropriate means, structures and management systems, as long as the methods are proportionate to major-accident hazards and are based on the principles set out in Annex III.

The directive also specifies that the operator must implement the MAPP via a safety management system (SMS). Annex III expands on this by saying that operators need to make sure their safety management system is suitable for the hazards, industrial activities, and organizational complexity of the organization. Facility managers must ensure that the SMS accounts for methods of identification and control of hazards, integration of safety into operations, and emergency planning, and define the organizational roles responsible for managing different aspects of safety.

The organization must have a management of change (MOC) process to ensure that all planned modifications to the facility or operations go through a formal review to assess and control potential risks before the changes go into effect. This is especially important to assess in the context of Seveso III because some planned operational changes may potentially change an establishment from lower-tier to upper-tier classification and change its corresponding regulatory obligations.

Finally, the SMS must involve performance monitoring. This includes reviewing key performance indicators (KPIs) and committing to a continuous improvement process that uses performance monitoring to identify opportunities to improve safety management.

What is a Safety Management System?

It might be worth parking on the SMS discussion for a while because an SMS is essential to comply with Seveso III and not all EHS managers fully understand what it is. .

To get a better handle on what an SMS is and should be, you should familiarize yourself with ISO 45001, the international standard for occupational health & safety (OH& S) management systems.

To understand why, let’s look at how ISO 45001 defines the term. In the “definitions” section, 45001 defines “management system” as a “set of interrelated or interacting elements of an organization to establish policies and objectives and processes to achieve those objectives.” In a note to the definition, 45001 further explains that “the system elements include the organization’s structure, roles and responsibilities, planning and operation, performance evaluation and improvement.”

In other words, an SMS isn’t something you can just buy and unbox because it consists of all the people, programs, policies, metrics, job-specific work instructions, and cultural aspects that collectively affect your environmental performance. It consists of your EHS team and all your employees from the shop floor to the C-suite, your individual facility’s environmental policy manual, and all the standard operating procedures (SOPs) for every work task with environmental aspects. A good shorthand to remember is that your system consists of “people,” “policies,” and “places” as show in the image below.

Following and especially certifying to ISO 45001 can not only help you improve your general safety and risk management practices but also can improve your compliance with the requirements of Seveso III. Look back at some of the Seveso requirements you’ve learned about. All of these are also facets of a successful management system as modeled by ISO 45001. For example, Section 6.1.2 addresses hazard identification and assessment of risks and opportunities, Section 8.1.3 addresses Management of Change, and Section 8.2 covers emergency preparedness and response.

ISO 31000 is another useful ISO standard to understand. Unlike 45001, ISO 31000 is not a standard that companies can certify to—it’s intended for guidance only. Still, it provides a broad framework to manage many kinds of risks, including not only OH&S or environmental risks but also financial risks and reputational risks that may follow a major chemical accident.

Establishment and Implementation of Emergency Plans

The emergency preparedness and response provisions of ISO 45001 are useful because they can help establishment management meet the analogous requirements in Seveso IIII.

All operators of facilities covered by Seveso III need to develop and implement an internal emergency plan describing their methods for responding to and minimizing the impacts of major accidents. The plans must also address how to communicate relevant information about the incident to the public, when necessary, and procedures to follow when cleaning up and disposing of chemical waste from a spill.

Operators of facilities classified as upper tier must also provide necessary information to the competent authority to develop external emergency plans that this authority could implement in the event of an accident at the facility. This information should include details about the identities and storage locations and quantities of chemicals at the site, and any other information the authority needs to develop adequate plans to respond to potential accidents at the facility involving those chemicals. Seveso III states that the authority has two (2) years from receipt of that information to develop an external emergency plan.

Leaders of global companies who are more used to regulations in say, the United States, may not be used to a regulation like Seveso III because it creates joint responsibilities for a facility manager and the local government authority for management and oversight of facility safety. This collaborative approach between the facility manager and the competent authority can only be effective if facility management can share accurate and readily understandable information about operations, including chemical storage practices. For example, the competent authority will need to know the identities and quantities of chemicals stored at the facility, along with the storage container types (e.g., 55-gallon drums, ASTs, totes, etc.) and their storage locations, because that information is relevant to planning emergency response procedures.

Identification of “Domino Effect” Risks

Managers of facilities subject to Seveso III must provide information to competent authorities identifying risks for “domino effects” from chemical accidents. The directive defines domino effects as situations in which “establishments are sited in such a way or so close together as to increase the likelihood of major accidents or aggravate their consequences.”

Seveso III also advises that operators who identify potential for domino effects should cooperate with each other. They should exchange appropriate information, and also cooperate in informing the public, including neighboring establishments, that major accidents could impact them.

The potential for external impacts, such as domino effects, are the reason Seveso III requires that decision making for specific individual projects at a Seveso III covered facility needs to involve public consultation, and public stakeholders in decision making. Facility managers can have legal liability if they do not involve the public in these matters. This again points to the need to have accurate and accessible information about chemicals that will be used, or the proposed workflows for facility changes.

Does the EU Provide Data on Chemical Accidents at Facilities Covered by Seveso III?

Yes. The Major Accident Hazards Bureau of the European Commission Joint Research Centre created a portal called MINERVA publicizing the details of major industrial accidents in the EU. The purpose of MINERVA is to provide the public with access to all information on current activities, relevant publications, and tools related to control of major accident hazards.

The Major Accident Hazards Bureau also sometimes issues reports summarizing data submitted by facilities covered by Seveso III. This includes a report about lessons learned from accidents in waste management facilities, and another on lessons learned from accidents in warehouses.

What are the Key Takeaways About Seveso III?

There are a lot of moving parts to Seveso III. Here are some of the key takeaways to help you maintain compliance with Seveso III and improve your SMS.

It Starts with Risk Management

As you learned earlier in this piece, the fundamental purpose of Seveso III is to address operational risk management practices. You need to have a good understanding of your facility and its operations to evaluate the probability of different accident risks and the potential severities of accident outcomes. You’ll also need intuitive and engaging ways to share information with your whole workforce about risk pathways and the importance of the controls you have in place to prevent or mitigate risks.

You’ll have an easier time managing operational risk if you have better tools. Modern operational risk management software tools facilitate easier completion of different risk assessment methodologies like hazard identification (HAZIDs), risk bowties, process hazard analyses, and Five Whys.

Know Your Chemical Inventory

Since the applicability of Seveso III depends on the storage levels of chemicals listed in Annex I, you’ll need to have a good understanding of your chemical inventory to determine if your facility is subject to the directive’s requirements.

The best chemical management software can help by providing barrier-free 24/7 access to your entire safety data sheet (SDS) library, and information about chemical and physical properties and hazards, safe storage practices, acute and chronic exposure symptoms, first aid measures, and cleanup/disposal procedures. If you’re an upper-tier facility, or even a lower-tier facility that wants to be as proactive as possible, chemical management software can also help you map your chemical storage locations onto a facility diagram that you can share with the competent authorities with oversight of your facility.

Don’t Forget Management of Change (MOC)!

There’s no use going through the effort to develop effective risk management practices if you don’t also have management of change plans in place to review planned changes to the facility or its operations that could affect risk levels. MOC is an essential part of your SMS as outlined by ISO 45001, because it helps you ensure that you’re getting a chance to assess and control risks from planned changes before those changes go live.

If MOC is so important, why doesn’t everyone do it? One of the main reasons is that without good technological support, MOC can be a tedious and time-consuming process. With the right MOC software, you’ll have an easier time reviewing workflows for proposed changes, and develop pre and post start-up checklists, automate alerts when review or approval tasks are coming due or past due, and maintain an audit trail for the whole workflow review process.

Let VelocityEHS Help!

Streamline and improve risk management with the Velocity Operational Risk Solution. Gain unparalleled visibility and control of workplace risks, drive enhanced collaboration and engagement with your stakeholders, and adapt and scale to your organization’s needs. You’ll have direct ability to conduct risk assessments such as HAZIDS, risk bowties, and PHAs, and keep your entire team aligned with risk management practices. We also offer effective and easy MOC capabilities that help you easily manage reviews and approvals of entire workflows of planned changes and provide an audit trail so that you know that all the right boxes have been checked before the changes go live.

Major facility accidents are scary, but operational risk management doesn’t have to be. Contact us today to schedule a demo and learn how we can help you comply with Seveso III and improve your risk management practices.