By Phil Molé, MPH

OSHA’s been busy over the last couple of years, and most discussion of their activity has focused on their rulemaking. But OSHA’s mission encompasses enforcement as well as regulatory action, and National Emphasis Programs (NEPs) comprise an important part of their strategy to plan and conduct enforcement inspections. OSHA has also been busy rolling out new NEPs targeting a variety of industries and areas of safety management. EHS managers need to understand these enforcement priorities to be better prepared for potential regulatory inspections. Here’s a summary of recent activity on NEPs and key takeaways.

What are OSHA NEPs?

OSHA NEPs are written statements of policy and procedure on a single subject, which generally include implementation guidelines and responsibilities for the Agency’s affected offices. Because OSHA is responsible for protecting the safety of employees at all worksites across the US covered under the Occupational Safety and Health (OSH) Act, they need a strategy to focus their enforcement efforts, so that they’re prioritizing the establishments and work activities with the most significant safety risks.

It’s important to understand that NEPs do not in themselves create any new regulatory obligations or modify any existing regulations. As OSHA states on their page for directives, “instructions available here are not standards, regulations, or any other type of substantive rule. No statement in these Instructions should be construed to require the regulated community to adopt any practices, means, methods, operations, or processes beyond those which are already required by the Occupational Safety and Health Act of 1970 (OSH Act) (29 USC § 668), or standards and regulations promulgated under the OSH Act.”

Even so, understanding OSHA’s NEPs gives you important insights into the agency’s enforcement priorities. This understanding helps you, as an employer, know how OSHA is prioritizing which establishments to inspect and what their Certified Safety & Health Officials (CSHOs) will be looking for once they conduct inspections.

What NEPs Has OSHA Issued Recently?

NEPs are nothing new, but OSHA’s activity in issuing new NEPs can fluctuate over time, based on agency priorities. For example, OSHA only issued one new NEP (on amputations in manufacturing industries) during the entire calendar year of 2019, although they did issue several geographically targeted Regional Emphasis Programs (REPs). But since April 2022, OSHA has issued three entirely new NEPs and has also significantly revised an existing NEP, an increase which clearly indicates that OSHA saw the need to shift their enforcement priorities. Here’s a closer look at these four recent NEPs and their implications.

OSHA’s Heat Exposure NEP

According to the U.S. Department of Labor’s Bureau of Labor Statistics (BLS), the effects of hazardous heat exposure resulted in an average of 35 fatalities per year and an average of 2,700 cases with multiple days away from work between 2015 and 2019. The actual numbers may be higher, because BLS indicates that heat-related fatalities may be underreported and improperly diagnosed due to failures to document when exposures to heat caused or contributed to “official” causes of death, such as heart attacks.

These trends influenced OSHA to begin focusing more on heat-related exposures in the past couple of years. For example, OSHA published an Advanced Notice of Proposed Rulemaking (ANPRM) in the Federal Register on October 27, 2021. OSHA’s stated purpose in starting to work on a heat exposure standard, according to the landing page for the ANPRM, is to “more clearly set forth employer obligations and the measures necessary to more effectively protect employees from hazardous heat.”

OSHA demonstrated that it was keeping the goal of protecting workers from heat exposures top of mind by rolling out an NEP on “Outdoor and Indoor Heat-Related Hazards” on April 8, 2022. The NEP lays out OSHA’s inspection and enforcement priorities to support reduction of occupational illnesses and fatalities from heat exposure.

Here’s a high-level overview of the NEP.

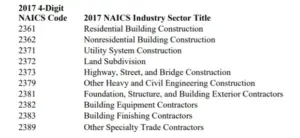

Site Selection: OSHA’s NEP contains an Appendix A of “Target Industries for the NEP” that lists the industry sectors, represented by North American Industrial Classification System (NAICS) codes, that they’ll be focusing upon for inspections purposes.

How did OSHA decide which NAIC codes to include? According to the NEP, inclusion of an NAICS in Appendix A results from:

1) High numbers or high incidence rates of heat related illnesses from BLS data;

2) Elevated number of days away from work or high numbers of severe cases of heat-related illnesses, as indicated by death or hospitalization, from OSHA severe injury reports made by employers; or

3) the highest number of heat-related general duty clause 5(a)(1) violations and Hazard Alert Letters (HALs) over a 5-year period (1/1/2017 through 12/31/2021), or the highest number of OSHA heat inspections since 2017.

Not surprisingly, Appendix A includes various subsectors of the construction industry, as shown in the image below.

Appendix A also includes subsectors as diverse as restaurants, bakeries, facilities support services, automobile dealers, farming, chemical manufacturing, vehicle manufacturing, and wholesaling of various goods. Consult Appendix A for the full list.

Timing of Inspections: The NEP states that programmed inspections will occur on any day that the National Weather Service (NWS) has announced a heat warning or advisory for the local area. Appendix G of the NEP lists the types of NWS weather alerts that employers should know, both because they’re important for the protection of their employees, and because OSHA is more likely to conduct inspections on those days. Appendix G works together with Appendix A discussed above, because on days that the NWS issues an alert listed in Appendix G, they will conduct inspections of facilities in the affected area that have NAICS codes listed in Appendix A.

Focus of Heat-Related Inspections: According to the NEP, OSHA’s compliance safety and health officers (CSHOs) conducting a site inspection shall open or refer a heat-related inspection for any hazardous heat conditions observed or recorded by the employee in the OSHA 300 logs or 301 Incident Reports they’re required to maintain under the Recordkeeping Standard. CSHOs will also open a case if an employee brings a heat-related hazard(s) such as lack of access to rest or shade, lack of acclimatization, and lack of proper training about heat hazards, to their attention during an inspection.

The NEP is currently in effect and applies “OSHA-wide,” (everywhere that federal OSHA has jurisdiction). States that have federally approved state OSHA plans are not required to adopt the NEP, but if they do so, they must adopt provisions at least as stringent as the federal NEP.

OSHA’s NEP on Falls

Fatalities caused by falls continue to be a leading cause of death for all workers. The tables below compile data on occupational falls from BLS and OSHA Information System (OIS) data between 2014 and 2021.

| All Industries | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

| Total fatalities | 4,821 | 4,836 | 5,190 | 5,147 | 5,250 | 5,333 | 4,764 | 5,190 |

| Fatal falls – slips/trips/falls | 818 | 800 | 849 | 887 | 791 | 880 | 805 | 850 |

| Fatal falls to lower level | 660 | 648 | 697 | 713 | 615 | 711 | 645 | 680 |

| Construction | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

| Total fatalities | 899 | 937 | 991 | 971 | 1,008 | 1,061 | 1,008 | 986 |

| Fatal falls – slips/trips/falls | 350 | 364 | 384 | 386 | 338 | * | 368 | 390 |

| Fatal falls to lower level | 345 | 350 | 370 | 366 | 320 | * | 351 | 378 |

*= BLS data not available for 2019

As the data shows, the number of fatal falls recorded for all industries as well as for construction has resisted falling during this time interval. OSHA, understandably, has always set high priorities for addressing industry and injury trends toward high fatality numbers. As a result, OSHA issued an NEP on April 24, 2023 (effective as of May 1, 2023) with the expressed goal to “significantly reduce or eliminate unprotected worker exposures to fall-related hazards in all industries that can result in serious injuries and deaths.”

The “Scope” section of the NEP notes that OSHA will be conducting all inspections related to falls in the construction industry based on the provisions of the NEP. For non-construction inspections, the NEP targets the following activities:

- Roof top mechanical work/maintenance

- Utility line work/maintenance (electrical, cable)

- Arborist/tree trimming

- Holiday light installation

- Road sign maintenance/billboards

- Power washing buildings (not connected to painting)

- Gutter cleaning

- Chimney cleaning

- Window cleaning

- Communication Tower

The NEP also notes that if OSHA inspectors observe employees working at height in other non-construction work activities, they may initiate an inspection if approved by area office management.

According to the NEP, CSHOs are authorized to initiate inspections whenever they observe someone working at heights, and that these observations may occur during the CSHO’s normal work-day travel or while en route to, from, or during, other OSHA inspections. Also, the CSHO may expand the scope of an inspection under this NEP if there is evidence from injury and illness records, plain view hazards, or employee interviews of other potential safety and health hazards or violations at the worksite.

Putting all of that together, if you’re an employer at a worksite that involves working at heights, especially in the construction industry or a work location that involves any of the ten activities listed above, you now have an elevated potential for OSHA inspections related to fall hazards.

OSHA’s Warehousing and Distribution NEP

BLS data shows that warehousing and distribution center operations have significantly higher overall rates of occupational injuries as well as a higher Days Away, Restricted or Transferred (DART) rate than the average rates for all industries. Some of the more common causes of injuries in this industry include:

- “struck by” incidents

- “caught-in-between” incidents

- slips, trips, and falls

- blocked aisles

- means of egress

- powered industrial trucks (PITs) such as forklifts

- heat exposure hazards

- ergonomic hazards, such as risks of musculoskeletal disorders (MSDs)

Adding to the urgency to address these hazards, the warehousing and distribution industry has seen significant growth in the last 10 years, with employment numbers surging from 668,900 workers in January 2011 to 1,713,900 workers (seasonally adjusted) in December 2021.

OSHA issued an NEP for the warehousing/distributions industry on June 14, 2023, which became effective July 13, 2023. The table below summarizes the specific NAICS codes associated with warehousing/distribution OSHA is targeting under this NEP.

| NAICS Codes | Establishments |

| 491110 | Postal service (processing & distribution centers only) |

| 492110 | Couriers and express delivery services |

| 492210 | Local messengers and local delivery |

| 493110 | General warehousing and storage |

| 493120 | Refrigerated warehousing and storage |

| 493130 | Farm product warehousing and storage |

| 493190 | Other warehousing and storage |

Many warehousing and distribution operations are connected to retail operations – they handle the storage of products until the retail arm of the same company is ready to stock them in their stores. OSHA is aware of this, and their NEP also recognizes that many retail establishments have the same or similar hazards as their warehousing/distribution branches and provides procedures for conducting partial safety inspections of certain retail establishments with the highest rates of injuries and illnesses. The table below summarizes the high injury rate retail establishments covered under this NEP.

| NAICS Code | High Injury Rate Retail Establishments |

| 444110 | Home centers |

| 444130 | Hardware stores |

| 444190 | Other building material developers |

| 445110 | Supermarkets and other grocery stores |

| 452311 | Warehouse clubs and supercenters |

The NEP covers both programmed (i.e., planned and scheduled) and unprogrammed inspections. According to the section on Inspection Procedures within the NEP, each inspection will begin with an opening conference in which the CSHO will verify the NAICS code of the establishment and verify the location where warehousing and distribution activities occur.

During the opening conference, the CSHO will also review OSHA 300 logs, 300A injury and illness summaries, and 301 incident reports for the current year and three previous calendar years to identify recorded injuries and illnesses associated with the focused hazards covered by the NEP. The NEP also states that when inspecting an establishment that had obligations to electronically submit 300A data to OSHA via the Injury Tracking Application (ITA) but did not submit, CSHOs will follow guidance listed in OSHA’s Interim Enforcement Procedures for Failure to Submit Electronic Illness and Injury Records under 29 CFR 1904.41(a)(1).

Notice that the NEP identifies heat exposure hazards among the common causes of injuries in the warehousing and distribution industry. That’s not the only intersection point between OSHA’s heat exposure and warehousing/distribution NEPs. The latter NEP states that CSHOs must assess occupational heat exposure risks during review of injury and illness records, during worker interviews, and during the establishment walkthrough. If CSHOS observe heat-related hazards occurring during the inspection, they need to expand the inspection scope to include the provisions of the previously discussed heat exposure NEP. The warehousing/distribution NEP also notes that it shares multiple target NAICS codes with the heat exposure NEP, and states that if an establishment is targeted under both the Warehousing and Distribution NEP and the Heat NEP, CSHOs may conduct safety and health inspections concurrently under both NEPs.

OSHA’s Revised NEP on Combustible Dust

OSHA has long recognized the dangers of combustible dust, including combustible dust in the definition of a hazardous chemical in the Hazard Communication Standard, and had issued a combustible dust NEP (CPL 03-00-008) in 2008.

However, two factors influenced OSHA to revise its Combustible Dust NEP. The first is that the numbers of combustible dust incidents remained high, with CSHOs issuing 3,389 violations from 910 programmed inspections and 1,253 un-programmed inspections conducted between fiscal years 2013 and 2017. The second factor is that OSHA wanted to ensure its NEP reflected the most recent details about industries and operations that most frequently had combustible dust incidents. According to the NEP, animal food manufacturing, sawmills, wood manufacturing (e.g., cut-stock, re-sawing and planing), and agricultural processing facilities (e.g., grain and field beans) experienced the highest numbers of combustible dust-related fatalities and catastrophes, and the Combustible Dust Safety Science’s Combustible Dust Incident Reports from 2016 to 2018 state that the majority of combustible dust hazards resulting in fires and explosions involved combustible dust generated during the manufacturing and processing of agricultural, food, wood, and metal products.

OSHA’s revised Combustible Dust NEP became effective on January 30, 2023, and cancels the 2008 NEP. The NEP notes the following industries are among those that generate or handle combustible dust:

- wood products, including lumber;

- agriculture;

- human food products;

- animal food products;

- chemicals;

- rubber;

- textiles;

- forest and furniture products;

- metal processing;

- tire and rubber manufacturing;

- paper products;

- 3-D printing;

- Pharmaceuticals;

- wastewater treatment;

- recycling operations (metal, paper, and plastic); and

- coal dust in coal handling and processing facilities.

A full list of targeted industries is included in Appendix B of the standard.

The NEP indicates that CSHOs conducting inspections pursuant to this NEP will include the following elements:

Plant History of Fires and Explosions: CSHOs will determine whether the establishment has had a history of fires or explosions caused by combustible dust, using techniques such as employee interviews as well as observations of buildings and process equipment, as well as review of OSHA logs, insurance claims, and local fire department records.

Review of Safety Data Sheets (SDSs): The NEP states that CSHOs should review SDSs for information that may indicate a particular dust is combustible, but also cautions that SDSs should be used for initial information only, and analytical tests are the only reliable way to determine if dusts at the establishment are combustible.

Review of Electrical Area Classification Drawings/Documents: CSHOs will review information about electrical areas to identify areas delineated as Class II, Division 1 or Division 2 and ensure electrical equipment is approved for the hazardous location.

Review of Employer Dust Hazard Analysis (DHA): The NEP instructs CSHOs to review the DHA the employer has developed and used to identify, evaluate the potential fire, flash fire, or explosion hazards associated with the presence of combustible dust at the establishment. The CSHOs should also observe all areas of the facility for evidence of buildup of combustible dust and should observe and verify what dust prevention measures the employer may have in place, such as explosion prevention systems on dry dust collectors, spark detection and extinguishing systems on ventilation, and dust reduction features on material handling equipment.

What are Major Takeaways from OSHA’s Most Recent NEPs?

You’ve absorbed a lot of information so far about OSHA’s recent NEPs. It might be helpful at this point to boil down our analysis of the recent NEPs into a handful of high-level takeaways.

There Are Plenty of NEPs, But Also Plenty of Coordination. While OSHA is issuing more NEPs, they’re also thinking more about how to coordinate their NEP efforts and find ways that their CSHOs can conduct inspections pursuant to more than one of these NEPs when conditions warrant it. For example, you’ve seen that the Warehousing and Distribution and Heat Exposure NEPs share many target NAICS codes, and that the Warehousing/Distribution NEP directly states that CSHOs should expand their inspection scope to include heat exposure if they observe evidence of heat exposure risks. What this means, in practice, is that based on their operations, some establishments may have multiple ways to find themselves at elevated risk of inspection, as well as elevated risk of noncompliance findings should OSHA inspect their worksite under one of these NEPs.

Get Your Injury and Illness Records in Order. Once OSHA CSHOs arrive at your establishment, they may review injury and illness records. In fact, the NEPs for Falls, Heat Exposures and Warehousing/Distribution all state that review of these records is part of the scope of inspections by CSHOs, and that CSHOs may expand their inspection or take additional enforcement actions based on their review of records. Also, the Warehousing and Distribution NEP states that if CSHOs find the establishment under inspection should have electronically submitted 300A data but did not, they will expand the scope in accordance with OSHA’s interim enforcement guidance for electronic injury and illness reporting. So, for many good reasons, including your own need to have accurate information about injuries and illnesses in your workplace to better reduce occupational safety risks, you need to ensure you have a solid, gap-free recordkeeping system. Here’s where best-in-class safety software can help by making it easy to document all workplace safety incidents, complete OSHA Forms 300, 300A and 301, and electronically submit injury and illness records to OSHA via the ITA.

Improve Your Management of Heat Exposure Risks. OSHA has been focusing more on heat exposure in recent years, having begun the rulemaking process for a heat exposure standard and issuing a Heat Exposure NEP. Additionally, the Warehousing/Distribution NEP directs CSHO to review heat exposure risks. If you haven’t yet systematically assessed your workplace and job tasks for heat exposure risks, both the increasing frequency of record temperatures and the increasing regulatory scrutiny from OSHA are creating some urgency to finally take heat exposure risks seriously.

Sharpen Your Risk Management Practices. At a high level, all the NEPs discussed in this article focus on an employer’s ability to manage operational risks. CSHOs inspecting establishments under these NEPs are going to be examining how well the employers are managing their risks, whether of work at heights, heat exposure, various warehousing/distribution work hazards, or combustible dust. Operational risk management software helps you assess and control a variety of workplace risks and share a common understanding of risk management with your workforce.

Have an Active Inspection Program. Inspections are one of the essential building blocks of an effective safety management program, because they help ensure you’re doing all the things you should be doing. Specifically, inspections are central to some areas of safety management addressed by these NEPs, including forklift safety in the warehousing/distribution industry (since OSHA requires at least daily inspections) and for combustible dust management, to make sure dust isn’t accumulating and increasing risks of fires and explosions. Best-in-class safety management software simplifies inspection management, making it easy to develop a site-specific inspection checklist and deploy it anywhere needed using a mobile device, attach photos and other documentation, and access inspection results from anywhere.

Let VelocityEHS Help!

Both incident management/recordkeeping and inspections are central areas of safety management systems that OSHA CSHOs will be focusing on during inspections conducted under NEPs. Our Safety Solution, part of our VelocityEHS Accelerate ® Platform, streamlines your incident management with mobile incident reporting capabilities, including the ability to quickly attach photographs and other documentation to the inspection record and easily complete Forms 300, 300A and 301. Best of all, we make it easy to generate electronic versions OSHA forms for easy transmission to OSHA via the ITA, and to cut down reporting time for multiple establishments by putting their data on a single .csv file. Our solution also strengthens your inspection program by enabling you to create inspection checklists tailored to your facility and operations, deploy them in the field via a mobile device, and have a central and readily accessible location for all your inspection data.

Of course, much of safety management broadly boils down to risk management. Our Operational Risk solution makes it easy to conduct risk assessments, focusing on heat exposure, combustible dust, working at heights or any other workplace risks, to manage controls, and to share important details about workplace risks with frontline workers.

OSHA’s NEP activity shows they’re taking workplace safety as seriously as ever – so it’s a good idea for you to take it just as seriously. Let us help. Visit our solution landing page for more information, or just contact us anytime.