Table of Contents

By Greg Duncan, MELP, CSP, Sr. EHS & ESG Content Manager at VelocityEHS

Job safety analysis (JSA) is one of the most widely relied-upon methods EHS professionals use to identify, assess, and control the hazards of job tasks. Job safety analysis is so valuable in performing this core occupational health and safety (OH&S) management function that OH&S regulators including OSHA, the Canadian Centre for Occupational Safety & Health (CCOSH), the UK Health & Safety Executive (HSE) and many others have all published volumes of guidance to help employers apply JSA in the workplace. Unfortunately, many EHS professionals still aren’t using this important tool to its full potential.

I had an enlightening experience recently at the 2024 Wisconsin Safety Council Annual Conference where I met with some folks after my session “Are Your JSA’s Good Enough? Don’t Wait for a Workplace Incident to Find Out.” In those discussions, I heard some interesting and inventive ways that attendees were managing job safety analysis at their organizations. For the most part, though, most businesses are still reliant on paper and/or spreadsheets for performing job safety analysis. This is despite the fact that modern JSA tools and technologies are available to help bring this incredibly valuable hazard and risk assessment tool to life in a way that paper or spreadsheet-based JSA methods simply can’t. This is particularly evident when we get to the risk assessment step of the JSA process.

Job Safety Analysis Risk Assessment

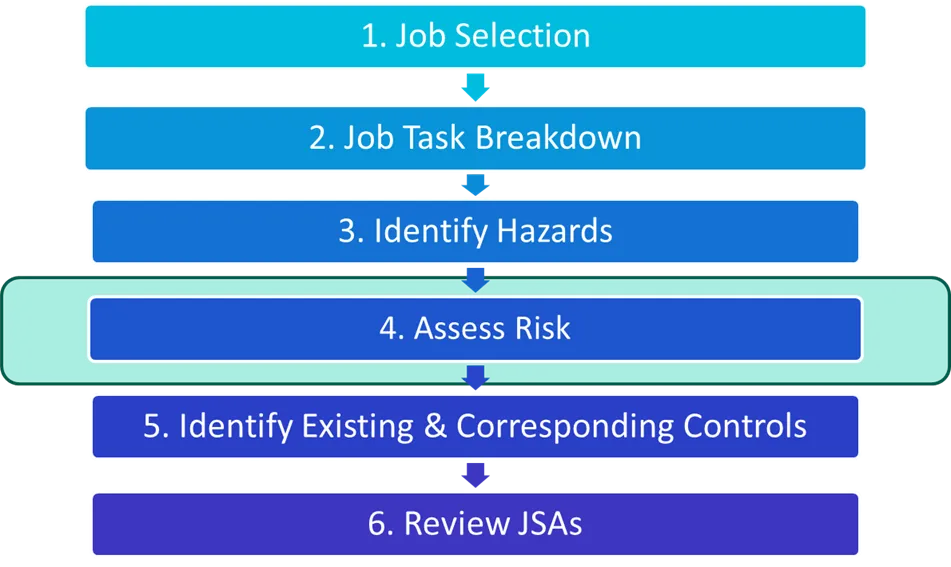

For a more comprehensive discussion of the JSA process (Figure 1) and JSA best practices, I’d invite you to check out our on-demand webinar “Are Your JSA’s Good Enough? Don’t Wait for a Workplace Incident to Find Out.” Here, however, let’s focus on the risk assessment step of the JSA.

Figure 1: The JSA Process

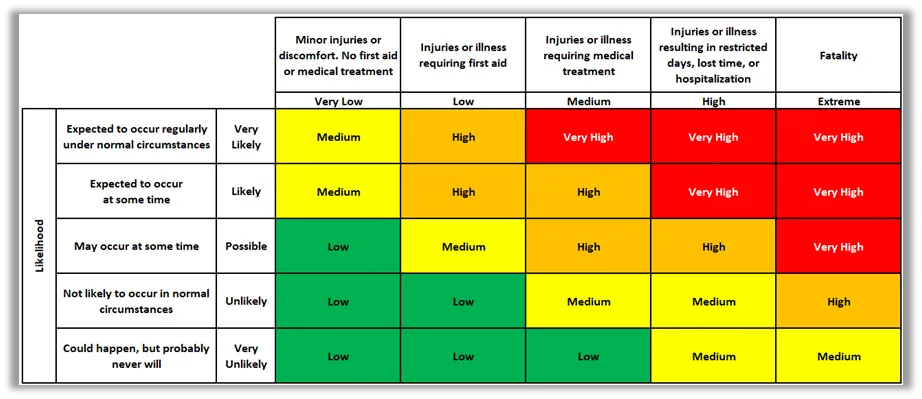

The JSA risk assessment step, like any other risk assessment, looks at potential risk causes (i.e., hazards) and asks what is the likelihood and severity of an accident or injury occurring as a result. These two fundamental risk factors (likelihood and severity) and overall risk score are commonly visualized using a basic risk matrix (Figure 2).

Figure 2: Sample Risk Matrix

A risk matrix offers a simple, qualitative means of evaluating risk likelihood and severity, while also providing an intuitive way to help prioritize and communicate the risks that have the greatest potential impact, cost, and consequence for the organization. Risks with the highest likelihood and severity fall in the upper-right of the matrix shown in red, while low-probability, low-severity risks fall in the lower-left in green.

This basic risk matrix is very common tool for JSA risk assessment, but it begs the question: “What are we actually basing our assessment of risk likelihood and severity on, and to what extent are we incorporating quantitative data to help assess these two critical risk factors?”

Expanding the Job Safety Analysis Risk Calculus

Data drives virtually every business decision-making process, and workplace safety should be no exception. EHS professionals need to be able to justify our actions, recommendations, and workplace safety improvements to many different stakeholders. That list can include regulatory agencies, management, workers, contractor providers, supply chain partners, insurance carriers, and many others. While qualitative assessment of risk likelihood and severity will always be part of the equation, hard data is increasingly becoming an essential part of the risk calculus.

So, when evaluating risk likelihood and severity, we should consider what quantitative data is available to better inform our JSA risk assessments. Even if we’re relying solely on our best judgement to assess risk likelihood and severity, we’re still ultimately basing those judgements around a number of safety metrics that describe risk likelihood and severity. So, why wouldn’t we formally account for these metrics in our calculation of risk to establish a more standardized, objective, and verifiable set of risk assessment criteria?

For example, let’s think about risk severity. Some metrics we might consider in our calculation of risk severity could include:

- Number of people impacted

- Exposure duration

- Exposure level/intensity

- Direct/indirect costs

- Lost time/productivity

Similarly, our assessment of risk likelihood relies on consideration of metrics such as:

- Injury or illness case frequency

- Exposure frequency

- Number of workers exposed

- Hours worked per job

As EHS professionals, we should always consider these metrics into our assessment of risk likelihood and severity if our goal is to improve the accuracy and reliability of our JSAs. I recognize that incorporating these metrics into our JSA risk assessments can sound like a lot of extra work, but to get a truly accurate picture of risk it’s absolutely necessary. The good news is that we’re ideally already collecting these safety metrics as part of our existing OH&S program. Unfortunately, this is where paper-based JSAs and even spreadsheets present significant obstacles, and we need to look toward tools like a purpose-built JSA software system that allows us to access and reference these metrics while performing the JSA and incorporate into the JSA risk assessment so we can simplify and expedite our risk calculations and more accurately assess JSA risks.

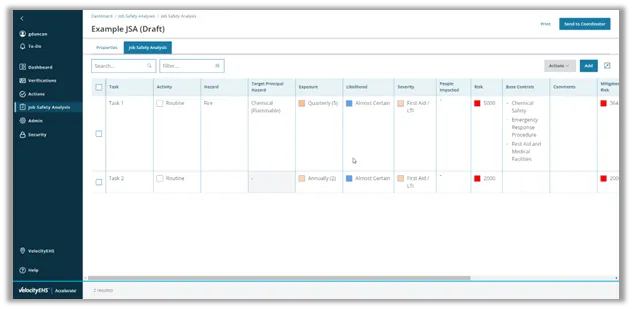

To illustrate this fact, let’s look at the example JSA (Figure 3) below:

Figure 3: Example JSA

Rather than a simple qualitative (high/medium/low) assessment of risk likelihood and severity, JSA software offers the ability to incorporate multiple semi-quantitative factors into the calculation of overall risk score. They are semi-quantitative because even though they still rely on a range of pre-defined categories to describe risk likelihood and severity, those categories are represented by a numerical value that is used by the software to calculate a quantitative risk score.

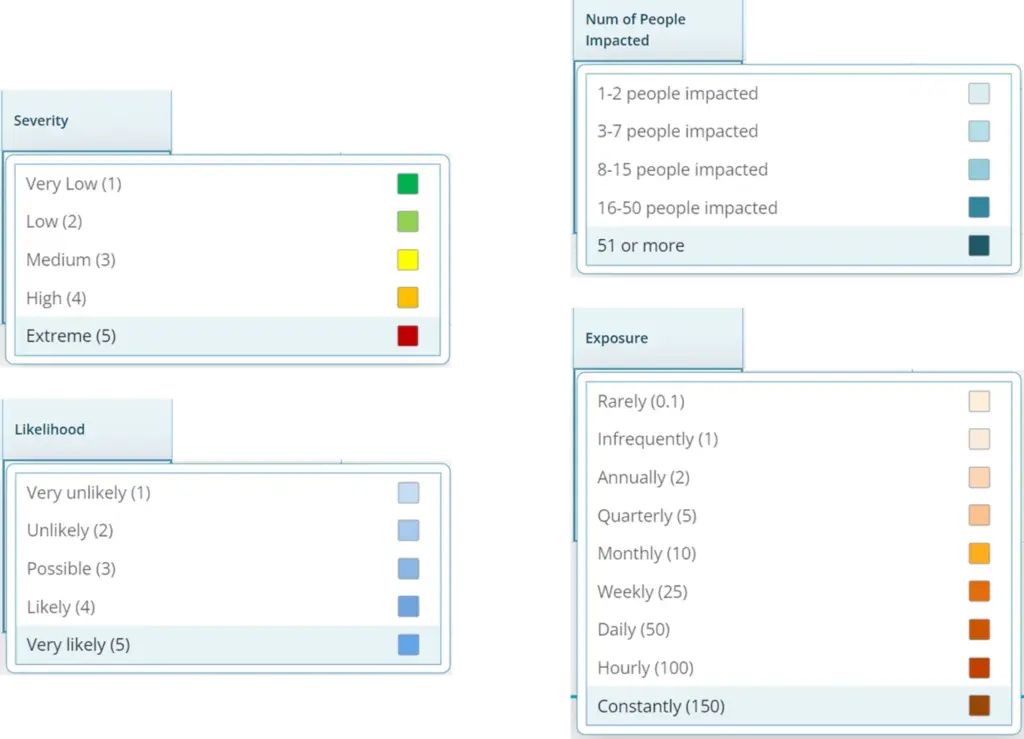

Figure 4: JSA Risk Assessment Variables

If we zoom in (Figure 4), we can see several semi-quantitative risk factors have been incorporated into the risk score calculation, resulting in a quantitative risk score that can then be objectively compared to other risk scores within the JSA to help prioritize job hazard control activities, or compared against the risk scores from other JSAs in the workplace or across the organization for reporting purposes and to support continuous improvement. VelocityEHS JSA capabilities allow for configuration of the JSA process to include consideration of these variables and other basic safety metrics (Figure 5) to help improve the accuracy and objectivity of our risk likelihood and severity assessments.

Figure 5: Additional JSA Risk Assessment Variables

Relying on semi-quantitative risk factors like the ones above rather than simple qualitative (high/medium/low) risk assessment criteria helps us to refine the accuracy and objectivity of our JSA risk scores. The trick is to ensure that metrics like injury and illness rates, incident rates, incident costs, exposure level, and exposure frequency are easily referenced while performing the JSA so we can use them to inform our assessment of these semi-quantitative risk factors. This is one of the key advantages of JSA software systems.

Standardizing Job Safety Analysis Risk Factors

In addition to improved accuracy and objectivity of JSA risk assessments, introducing semi-quantitative risk factors into the JSA also helps to standardize workers’ perceptions of risk and how those risks are assessed from job-to-job and across the entire organization. Risk perception is unique to every individual, and is influenced by multiple variables including workers’ level of experience and skill, past exposure to risks, and degree of risk tolerance or risk aversion. What one worker considers to be a medium risk, another may perceive as a high risk, even when looking at the exact same job task performed under identical conditions. You can imagine how this could introduce significant disparities in how risk likelihood and severity are assessed from one JSA to the next.

By using more objective, semi-quantitative risk factors and building these into the JSA process, we’re able to establish a standardized set of criteria for how risk likelihood and severity are assessed, minimize the impact of disparities in risk perception, and ultimately improve the accuracy of how risk scores are calculated. Within a single JSA, this enables EHS professionals to compare initial and residual risk scores in a more consistent manner so that each time the JSA for a given job is reviewed, we’re able to verify that the controls we’ve selected are truly effective at reducing risks. When looking at JSAs for jobs across multiple locations, this standardization allows for an “apples-to-apples” comparison of job safety and control effectiveness across the organization.

Our VelocityAI Hazard Analyzer and Control Recommendations co, powered by Vélo, implement risk scoring by identifying patterns in task descriptions and suggesting appropriate controls, improving both accuracy and speed.”

VelocityEHS JSA Capabilities

As EHS professionals, we need to be able to easily reference our safety metrics and factor those into our assessments of risk likelihood and severity. We need to be able to share and compare JSA information across the organization to help ensure job safety is managed using a consistent and standardized process. We need JSAs that actively contribute to continuous improvement of worker safety, and don’t simply sit on the shelf. JSAs should be living documents that provide workers with a dependable resource for understanding safe work practices, while simultaneously helping EHS professionals to better understand and control workplace risks. Spreadsheets unfortunately lack the functionality and flexibility that is necessary to get the most from JSAs and use them to their full potential.

VelocityEHS Job Safety Analysis capabilities, part of our Operational Risk solution, is purpose-built JSA software that helps you standardize the JSA process across your entire organization and efficiently manage it from a central dashboard. Users get a flexible, intuitive JSA management tool that makes it easy to accurately identify hazards to your workers, assess risks confidently and consistently, select, assign and verify risk controls, and communicate vital JSA information in real-time to help prevent incidents and continuously strengthen worker safety.

Ready to see how our JSA capabilities can help you? Click here to request a demo and speak with one of our EHS experts today!