By Phil Molé, MPH

Ergonomics is experiencing a significant shift, thanks in large part to 3D motion capture technology.

In the past, manual musculoskeletal disorder (MSD) risk assessments and their results were riddled with human error and inconsistent, subjective judgments, and inefficiencies in the process. Advancements were made in 2017, when Humantech Inc and Kinetica Labs (VelocityEHS companies) partnered to introduce the first commercially scalable software that used computer vision technology to complete risk assessments for work-related musculoskeletal disorders (MSDs) without special equipment, just a video recorded from a mobile device. This innovative method for assessing risk proved to be more accurate than human observers and faster to deploy in industrial settings.

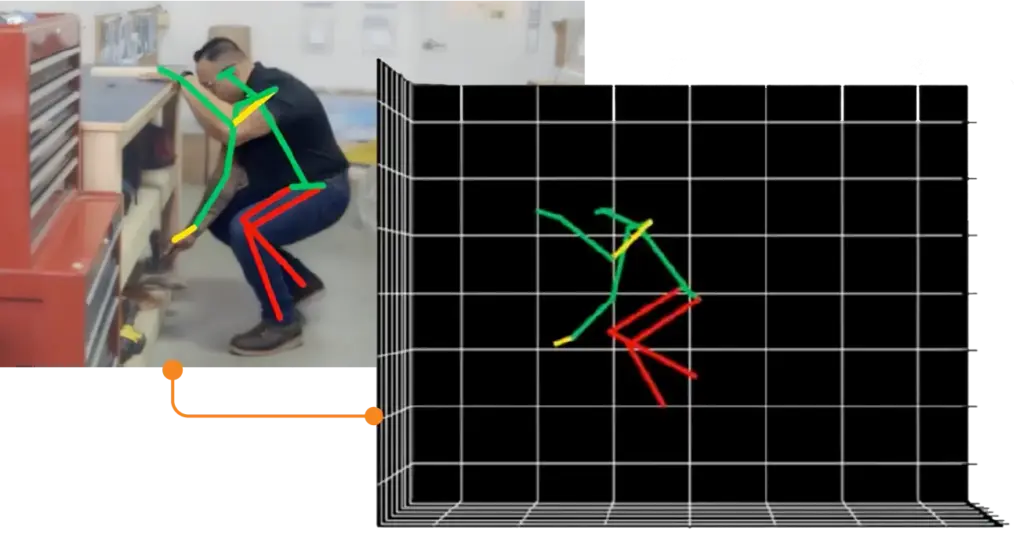

Despite these advantages, this 2-dimensional computer vision model had limitations, such as variability in results depending on camera angles, and the inability to properly assess joints hidden from view or wrist angles.

Now, with the introduction of a 3D model for motion capture, we’re witnessing a game-changer in the accuracy and reliability of assessment results, while it’s even easier to capture better data with your mobile camera, with no special equipment needed. This cutting-edge technology offers a more comprehensive picture of how workers move, and highlights the risks involved in postures and frequency of movements required for their work. By incorporating this technology into your ergonomics process, you can proactively identify issues that could lead to long-term health risks.

How 3D Motion Capture Transforms Ergonomics Assessments

Accurate Joint and Movement Analysis

Compared to traditional observational assessment methods and even the previous 2D models, the 3D motion capture in VelocityEHS Industrial Ergonomics tracks movements and provides the model with considerably more data to more precisely calculate risk.

This includes the incorporation of wrist angle data, as well as the accurate prediction of risk in joints that are hidden from view for periods of time during the assessment, resulting in a more accurate, reliable and comprehensive assessment of risk. That means that, no matter what your camera angle is when filming a job, the risk calculation will be the same using the 3D model. Further, this improved accuracy allows your organization to easily prioritize which high risk jobs you should address first, for the greatest impact in preventing MSDs before they develop.

Eliminating Subjectivity with Objective Data

A major struggle in traditional assessment methods is the subjectivity involved, whether through visual observations or self-reported data. There’s a reason why Certified Professional Ergonomists (CPEs) go to school for a number of years to be able to accurately assess MSD risk; without guidance, the average person just won’t be able to get the same level of accuracy.

3D motion capture removes this variability by providing objective, quantifiable data so that everyone can achieve accurate results through the simple process of recording a video on a mobile device. This increases the reliability of your ergonomics process as a whole, improving MSD risk reduction across your organization.

Integration with Advanced Ergonomics Software

Your ergonomics assessment technology should integrate with a complete ergonomics system, one that includes root cause analysis, improvement tracking, training on ergonomics principles and reporting.

The best 3D motion capture systems integrate with ergonomics software, allowing businesses to assess potential injury risks within regular job tasks. This comprehensive risk analysis helps the ergonomics team design targeted interventions, enabling companies to implement effective ergonomic strategies without the guesswork.

The Clear Benefits of 3D Motion Capture for Employees

At its heart, ergonomics is all about improving employee health and well-being and performance. The accurate data that 3D motion capture provides compounds upon the benefits that employees experience from good ergonomics, such as….

Reduced Risk of MSDs

With precise data and in-software guidance on identifying the right root causes and controls to put in place, those managing ergonomics at your organization can create more effective prevention strategies, significantly lowering the risk of MSDs—common and costly workplace injuries. Identifying risk factors early means proactive measures can be taken to keep employees safe, which aligns with the prevention strategy recommended by OSHA and other safety and health experts.

Improved Comfort and Productivity, Employee Satisfaction and Retention

Improving workstations based on accurate assessments leads to less strain and discomfort for employees. These changes not only boost productivity but also enhance job satisfaction, as workers can focus more on their tasks without the distraction of pain.

When companies prioritize health and safety, employees feel valued. A commitment to ergonomics fosters a culture of trust and well-being, significantly enhancing employee engagement and retention. By involving employees in the ergonomics process, companies can create an environment where safety and well-being are shared responsibilities, driving long-term engagement and success.

The Future with AI and Machine Learning

Alongside 3D technology, advancements in Artificial Intelligence (AI) and Machine Learning (ML) are further revolutionizing the ergonomics process. By integrating AI with 3D motion capture, businesses can conduct assessments faster and more accurately, minimizing human error and providing expert insights for root cause analysis.

Using just a video taken on a mobile device camera, 3D ergonomics tools like VelocityEHS Industrial Ergonomics can capture high-quality data and process it faster. This rapid assessment capability enables companies to identify and address risks swiftly, ensuring safer work environments sooner for employees. Even better, VelocityEHS Industrial Ergonomics facilitates your ability to actually use your assessments to reduce MSD risk levels through embedded expertise to help identify root causes and select appropriate controls.

Again, it’s the incomparable value of a proactive approach, as opposed to a reactive one.

The Benefits of AI-Driven 3D Motion Capture Ergonomics Assessments

- Minimized Human Error: AI reduces subjectivity and variability, ensuring consistent, reliable data.

- Faster Assessments: Automated processes speed up assessments, decreasing downtime and boosting efficiency.

- More Comprehensive Assessments: With the ability to incorporate data from joints temporarily hidden from view, the model provides a more complete picture of the risks of a job than 2-D assessments can provide.

Watch now: VelocityEHS Ergonomics: Value of the 3D Model for Customers

3D motion capture with AI is transforming workplace ergonomics with its precision, speed, and objectivity, far surpassing the traditional, human methods of ergonomics assessment.

By leveraging AI and machine learning with 3D motion capture, businesses can more reliably create safer work environments, reduce injury risks, and promote employee health and satisfaction. The VelocityEHS MSD risk assessment model—purpose-built for industrial and ergonomic applications—delivers a level of sophistication and relevance that traditional methods simply cannot match, making it a key tool for any company committed to continuous improvement, safety, and well-being. Whether you are a small business or a large corporation, embracing these advanced technologies marks a significant step toward building a culture of safety and proactive risk management for your workforce.

Let VelocityEHS Help!

VelocityEHS is just the partner you’re looking for to implement a successful ergonomics process. Our powerful AI-driven SaaS global enterprise ergonomics solutions deliver continuous improvement and are backed by the industry’s largest team of board-certified ergonomists.

We understand that it’s not just doing ergonomics assessments that matters; it’s using the assessments to improve workplace safety. That’s why the 3D Model for Motion Capture in our VelocityEHS industrial ergonomics software provides the most comprehensive MSD risk assessment available, incorporating automatic scoring of wrist bending and back twisting, and even capturing data from hidden body segments. You’ll also be able to conduct assessments from anywhere using a mobile device and then rely on powerful AI capabilities that help you identify risks and root causes and select better controls from expert-curated drop-down menus, so you can put your assessments to their intended use. You’ll have greater confidence in your assessments and overall ergonomics process.

And those are just some of the ways we can support you – in fact, Industrial Ergonomics is just one of four world-class solutions on our VelocityEHS Accelerate ® Platform, along with Safety, Chemical Management, and Operational Risk, all on one platform with an integrated user experience. Contact us today to learn more about how we can help you improve worker health and safety, or better yet, schedule a demo.