Once a job task in a facility has been evaluated for the risk of developing a musculoskeletal disorder (MSD) and the risk has been quantified, it’s time to implement solutions. If you’re going to effectively reduce MSD risk, you need to understand which risk factors are contributing most to the overall score and utilize control measures that impact the risk exposure. This way, you can ensure that your time, money, and resources are spent most effectively.

How can you ensure that your team’s ergonomics improvement solutions will give you the highest MSD risk reduction?

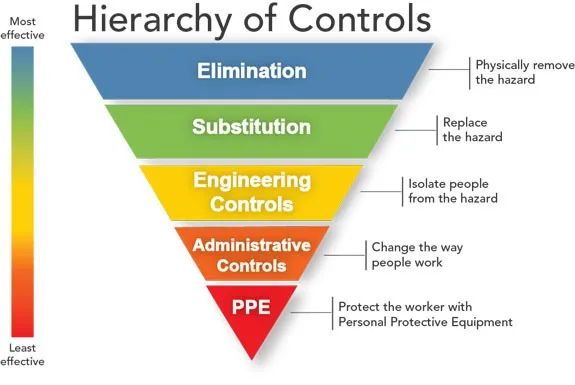

Consider the hierarchy of controls to brainstorm improvement solutions and reduce MSD risk.

The hierarchy of controls is a system used to minimize or eliminate exposure to hazards and is as follows: eliminate risk, change your workplace equipment to reduce risk, use administrative controls, and establish work practices to reduce risk.

The four main contributing factors for evaluating MSD risk in a job task are high forces, awkward postures, high frequencies, and long durations. While all factors are problematic, current research suggests that high forces are the greatest predictors of injury. This isn’t to say that the other factors aren’t problematic. However, whenever high forces are present, designing out the high force with engineering controls or reducing the force requirement will likely give you your greatest MSD risk reduction in your job task.

Here are some examples of controls, in order of greatest to lowest risk reduction:

- Eliminate risk by automating the process of a heavy lift.

- Change workplace equipment to reduce risk by reducing the weight of an item being lifted.

- Use administrative controls to provide a relief worker to reduce the frequency of a heavy lift.

- Establish work practices by lift coaching.

Think of permanent improvement solutions for MSD risks.

Many people think that a good solution for reducing MSD risk would be to have employees rotate through job tasks so that no one person is working a high-risk job for an extended period of time. But when considering ergonomics improvement solutions, it’s important to understand that job rotation is meant to be used as a temporary solution while you’re designing other engineering controls. Implementing a job rotation will only reduce the frequency of the lift and not the high forces involved. To make job rotation a permanent solution would mean that you’re now exposing more operators to these high forces, resulting in a high-risk job exposure for more people, instead of eliminating the risk or creating an improvement following the hierarchy of controls.

By considering MSD risk factors and the hierarchy of controls when creating ergonomics improvement solutions, you’ll ensure that your solutions will give you the greatest risk reduction for a job task.