Like many other EHS management processes, your ergonomics process should be built around three fundamental elements: identifying and assessing the risks to your people and workplace (in this case, musculoskeletal disorders [MSDs] and other ergonomics-related injuries), selecting and implementing the ideal controls and improvements to minimize those risks, and monitoring and refining the effectiveness of those controls and workplace improvements over time to ensure maximum risk reduction.

Here, we’ll look at these individual process elements and some of the common challenges encountered at each step. We’ll also highlight how the VelocityEHS ActiveEHS® methodology combines innovative technologies like artificial intelligence (AI) and machine learning (ML) with the deep, embedded expertise of our team of certified professional ergonomists (CPEs) to overcome those challenges and make world-class ergonomics processes achievable for EHS professionals at all levels.

Identifying & Assessing MSD Risks

When conducting a MSD risk assessment, collecting accurate and reliable data is critical. This data is the ultimate source for any conclusions we make about the root causes of MSD risks, and it will also define the controls or improvements we implement to manage those risks. Along with ample training, assessment data should help assessors to accurately characterize the MSD risks of the job tasks being performed, and should include:

- Surface Heights

- Hand Working Height

- Horizontal Reaches

- Forces

- Employee input & feedback

For more information on ergonomics assessment data collection, check out our blog on key ergonomics measurements.

The Challenge with MSD Risk Assessment

Certified professional ergonomists (CPEs) often rely on observational MSD risk assessment methods to assess MSD risks. There are numerous techniques that assessors apply during an observational-based assessment, and differing levels of familiarity and expertise in performing these assessment techniques introduces significant variability in measurements and other assessment data. As a result, assessment scores are often inaccurate and unreliable.

How significant is this variability? A 2017 study published in Human Factors, The Journal of the Human Factors and Ergonomics Society (HFES) analyzed 442 risk assessments of actual jobs carried out by 290 professionals from 20 countries to determine the reliability and accuracy of assessment data. The results showed that approximately 30% of the assessments performed using observational methods had errors. In 13% of the assessments, the errors were significant enough to invalidate the results of the assessment altogether. In total, nearly 1 out of 3 observational assessments performed in actual work situations did not adequately evaluate the level of potential MSD risks.

The study concluded that greater effort is needed to ensure that assessors possess better knowledge of the techniques used to assess MSD risks. Our first reaction to this conclusion might be that assessors require additional training and higher levels of expertise to ensure assessment accuracy, but this is another challenge which may not be easy to overcome. CPEs spend years of their careers developing that level of expertise, and most organizations may not have the budget or access to bring on one or more CPEs to perform those assessments.

However, ergonomics expertise can be supplemented with technology to enable non-experts to assess MSD risks more accurately. The right technology does this by automating and standardizing assessment data collection, and guiding assessors toward better decisions.

Motion Capture Assessment Technology

The goal of ergonomics assessments outside of the research laboratory is typically to prioritize intervention efforts (i.e., MSD risk controls) and quantify improvement effectiveness. As a matter of cost, observational-based assessments have traditionally been favored in industrial environments, at the unfortunate cost of data accuracy.

AI and machine learning are introducing new and exciting possibilities for improving the accuracy and simplicity of assessing MSD risks. Motion capture technology has been the state-of-the-art for evaluating whole body movements in research settings for over 20 years. However, it has only recently become feasible to apply this technology to MSD risk assessments in manufacturing and other industrial environments.

Originally, motion capture required the subject of the assessment to wear a large array of body sensors while the data was collected from multiple cameras to precisely record body movements. Today, the use of machine learning and artificial intelligence has eliminated the need for multiple cameras and sensors.

Sensorless motion capture provides a high level of accuracy in classifying posture ranges that is nearly the same as that obtained with body sensors, while requiring less time and cost to complete, less training for users to perform assessments, less interruption to operations, and the only special equipment needed is a cell phone or tablet to record a video of the job task.

Motion Capture vs. Observational Assessment

Motion capture, whether using sensors or sensorless technology, provides considerably more accurate data than observational assessments. Sensorless motion capture is even more accurate at identifying postures than observational assessments performed by experienced ergonomists, and substantially more accurate than those from non-experienced assessors. Practically—and most importantly—this means that an inexperienced ergonomics team member using sensorless motion capture can assess a job with similar accuracy as an ergonomics specialist.

There’s also the variable of time. No matter how experienced an assessor may be, it is hard to collect accurate information about body motions and postures over time throughout performance of complex job tasks. Although this is an important factor, most observational tools don’t include more than two data points of exposure. Motion capture provides the ability to accurately capture this data and apply multiple levels of exposure. In fact, time spent performing multiple movements and in multiple postures is continuously recorded, resulting in high resolution data that helps refine quantification of risks and better prioritize risk controls.

Additional benefits of motion capture assessments include:

- less time to learn how to perform an ergonomics assessment

- less practice to complete an ergonomics assessment accurately

- allows non-experts to accurately complete assessments, further reducing the cost per assessment.

This last point is perhaps the most valuable. The cost savings per assessment is substantially higher, as a much wider range of people in the organization can accurately complete an assessment. In some cases, the cost savings for an assessment can exceed 50%.

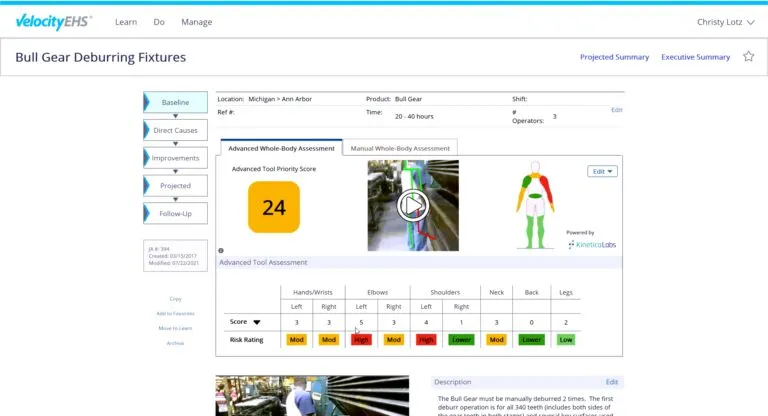

Figure 2: AI-generated baseline MSD risk assessment

By simply recording a video of a worker performing the job (Figure 1) and collecting a few pieces of additional information, EHS team members can provide everything the artificial intelligence requires to identify postures and forces that may be contributing to MSD risk (Figure 2).

For more information on VelocityEHS Motion Capture AI assessment technologies, read our blog on The Benefits of Sensorless Motion Capture for Ergonomics Assessments.

Implementing Effective MSD Risk Controls & Workplace Improvements

Once a baseline analysis of MSD risk is complete, then comes the task of identifying the root causes for those risks and selecting the most effective controls to manage them. The challenge here is that with potentially numerous job types involving a wide range of equipment and materials, not to mention all the other conceivable variables that figure into how jobs are performed, it can be incredibly difficult to determine true root causes for MSD risks, let alone select the most appropriate or effective controls. Unless you’re a trained ergonomist, it can be difficult to know where to start.

For example, consider the following MSD risk assessment scenario:

A manufacturer has a process for painting parts. The parts are large and have complex shapes, requiring a wide range of motions for the workers moving, prepping, and painting them. Parts are mounted on fixed brackets while they are painted, and the painters need to reach, twist, kneel, stoop and move around the parts to paint them. While this might not seem so bad when painting one part, the paint department completes hundreds of parts daily. The repeated motions required to paint the parts have resulted in multiple workers reporting back pain, hand/wrist strains, neck pain and general soreness. It’s a multi-task job with potentially several MSD risks, but let’s assume for a moment that you have already used VelocityEHS Industrial Ergonomics to perform the assessment and quantify the baseline for MSD risks to workers. Then what?

MSD Risk Causes

Well, you first need to define the causes of these MSD risks. In your parts painting scenario, one potential cause is the positioning of the parts while being painted. Are workers required to lift, move and fix the parts to the bracket? Excessive or repeated lifting forces and handling of the parts can also contribute to these risks. Is repeated motion with the paint sprayer causing hand and wrist strains? These are just a few potential causes for the overall job MSD risk, but clearly identifying the true root causes is fundamental to the effectiveness of your MSD risk controls and workstation improvements.

MSD Risk Controls

What are some potential controls for these MSD risk causes? One possible alternative would be to mount the parts to a moveable mount/bracket that can be raised, lowered, or rotated so that the painter can maintain a comfortable posture while painting the part. For potential strains from moving the parts onto or off of the painting mount/bracket, consider using some type of cart, conveyor or lift system to minimize/eliminate the need to manually lift and transport the parts. To address hand and wrist strain from using the paint sprayer, consider replacing it with a sprayer with a more ergonomically suitable handle/grip frame and balanced design, or perhaps some type of mechanical assist that minimizes forces required to hold and move the sprayer. There are many possibilities for alternative controls, but one thing to remember—EVERY individual MSD risk identified during your assessment should have a root cause (potentially multiple causes) attributed to it, and you must address each of those causes with a corresponding control or improvement.

The Challenge…

Even an experienced CPE with close knowledge of the jobs and workstation designs being assessed may find it difficult to identify the root causes of the associated MSD risks, let alone select the most appropriate and effective controls for each root cause. For example, one thing that you might not immediately think of in our parts painting scenario would be to automate the painting process altogether—using robotics to move, mount, and paint the parts rather than exposing workers to the MSD risks (not to mention the chemical exposure and other safety risks) inherent to the painting process. When it comes controlling MSD risks in industrial settings, engineering and ergonomic design principles will factor heavily into both identification of root causes and selection of MSD risk controls, and this can make non-ergonomics experts feel a little lost.

ActiveEHS®-Driven MSD Risk Controls

VelocityEHS Industrial Ergonomics includes ActiveEHS®-driven MSD risk controls that are designed to guide users of any experience level through a standardized workflow that, following establishment of the baseline MSD risks, prompts users to choose which areas to prioritize. From there, you can select from a pre-built list of potential causes and controls for the MSD risks. These pre-built cause and control lists have been painstakingly assembled with the collective expertise of our in-house team of CPEs who possess hundreds of combined years of experience in assessing and designing controls for MSD risks in a wide range of industrial environments. This enhancement empowers your entire team to more quickly and accurately identify risks, root causes and controls, helping save time and improve risk reduction.

Monitoring Control Performance & Refining Workplace Improvements

Like any other EHS management program, sustaining your ergonomics process over time means taking a continuous improvement approach. Even a well-designed MSD risk control or improvement may not initially be the most effective, and controls should ideally be reassessed and refined on a continuous basis. That means having ways to track control effectiveness. In other words, it means MSD risk metrics and indicators.

MSD Risk Metrics

Many large employers measure and report on MSDs as a part of their ESG program to quantify how they are maintaining safe workplaces. At a very basic level, you only need a couple of key metrics (key performance indicators, or KPIs) to drive your ergonomics improvement process:

- Percentage of job tasks with a high level of exposure to MSD risk factors

- The percent reduction of MSD risk achieved through ergonomics improvements

These two simple metrics can tell you a lot about the effectiveness of your ergonomics process improvements, but merely collecting these data is not enough. All of the time, effort, and resources you devote to your ergonomics process will go un-recognized unless you can effectively communicate successful reductions in MSD risks and demonstrate the value of your ergonomics process to the business.

Program Transparency & Visibility

To make these metrics meaningful and add value to your organization, you should add them to your organization’s performance dashboard and communicate them to management and your teams on a regular and periodic basis. Adding the measures to an organization’s data dashboard and performance scorecard not only promotes transparency of performance, but it also sends the message that MSD risk reduction (i.e. employee safety and well-being) is equally as important as productivity, quality, and financial performance metrics and goals. In addition, regular review and discussion of these metrics at the management level reinforces the priority that leadership places on reducing MSD risks, providing a safe workplace, and holding the right people accountable for risk reductions.

VelocityEHS Industrial Ergonomics packages our cutting-edge Motion Capture AI assessment tools and ActiveEHS®-driven MSD risk controls within a comprehensive program management solution that ensures organizations can easily coordinate, track and manage MSD risk assessment, analysis and controls across jobs and locations from one centralized system. With standardized, reliable, and repeatable assessment processes and automation of time-consuming manual assessment tasks, our software allows ergonomics experts and non-experts alike to accurately measure and prioritize MSD risks at scale, saving valuable time that can be better spent implementing improvements that positively impact worker health. At the same time, intuitive controls and centralized access to program data helps ensure continuity of best practices for controlling MSDs even with turnover of ergonomics management personnel.

In addition, data dashboards and reporting features provide ergonomics teams with heightened visibility of the data they need to understand key trends while also enabling them to drill down into the data for a more granular analysis when needed. The system also makes it simple to generate an easy-to-understand executive summary report that includes essential details of MSD risks, controls and improvements, trends and other KPIs to help ergonomics teams easily communicate the value of your program to management.

VelocityEHS Industrial Ergonomics Software Just Got Even Smarter

VelocityEHS® Industrial Ergonomics combines on-demand training, pioneering sensorless motion-capture AI technology, ActiveEHS®-driven MSD risk controls, and comprehensive program management capabilities so you can spend less time trying to identify the problem and more time making improvements and effectively controlling risk.

Give us a call or Request a Demo to learn how VelocityEHS can help you implement and maintain a world-class ergonomics process for your business.