Standardize your JSA Process with Job Safety Analysis Software

Create a standardized JSA process that works for your organization. Ensure data accuracy and easily identify and calculate risk to prevent injuries and illnesses for workers. Great news: JSAs are available on the Accelerate Platform.

![]() Standardize JSAs with configurable templates

Standardize JSAs with configurable templates

![]() Improve accuracy & auto-calculate risk scoring

Improve accuracy & auto-calculate risk scoring

![]() Gain real-time visibility into JSAs with custom dashboards

Gain real-time visibility into JSAs with custom dashboards

Job Safety Analysis software helps you efficiently manage the entire JSA process across locations – to accurately identify hazards to your workers, easily verify controls and prevent dangerous and costly incidents from occurring. Available on the on the VelocityEHS Accelerate® Platform.

JSA Core Capabilities

Configurable JSA Template

Base Control Library

Standardized Worksheets

Hazard and Control Trending

Risk Reduction Action Items

Auto Risk Calculation

Configurable JSA Template

Base Control Library

Standardized Worksheets

Hazard and Control Trending

Risk Reduction Action Items

Auto Risk Calculation

Video

Getting More from Your JSA Process

The new Job Safety Analysis (JSA) capability in VelocityEHS Operational Risk is designed to standardize JSA across your locations, simplifying and streamlining this essential safety and risk management process to help you get more from much less effort.

Watch the quick video to learn more.

Benefits of VelocityEHS

Job Safety Analysis (JSA) Software

Standardized JSA

Processes

- Reduce data variability with JSA templates configured to your organization’s process

- Determine severity, likelihood, number of people involved and exposure of identified hazards

- Create a library of base controls with associated risk reduction factors

- Assign actions & automate notifications for deadlines.

Improved Data Accuracy & Utilization

- Reduce data entry errors, create consistency, improve efficiency

- Identify trends in hazards and controls across all tasks and locations

- Auto-calculate risk score from entered hazards and risk reduction factors

- Get better insight into risk control strategy

Greater Visibility &

Engagement

- Get real-time visibility into the status of ongoing JSAs, hazard assessments and action items

- Customize dashboards to display specific safety metrics

- Boost collaboration with unlimited users & worksheets

Infographic

JSA Software Helps Solve the Puzzle of Risk

Download now to see how to make this risk analysis process simpler, faster & more valuable for your organization.

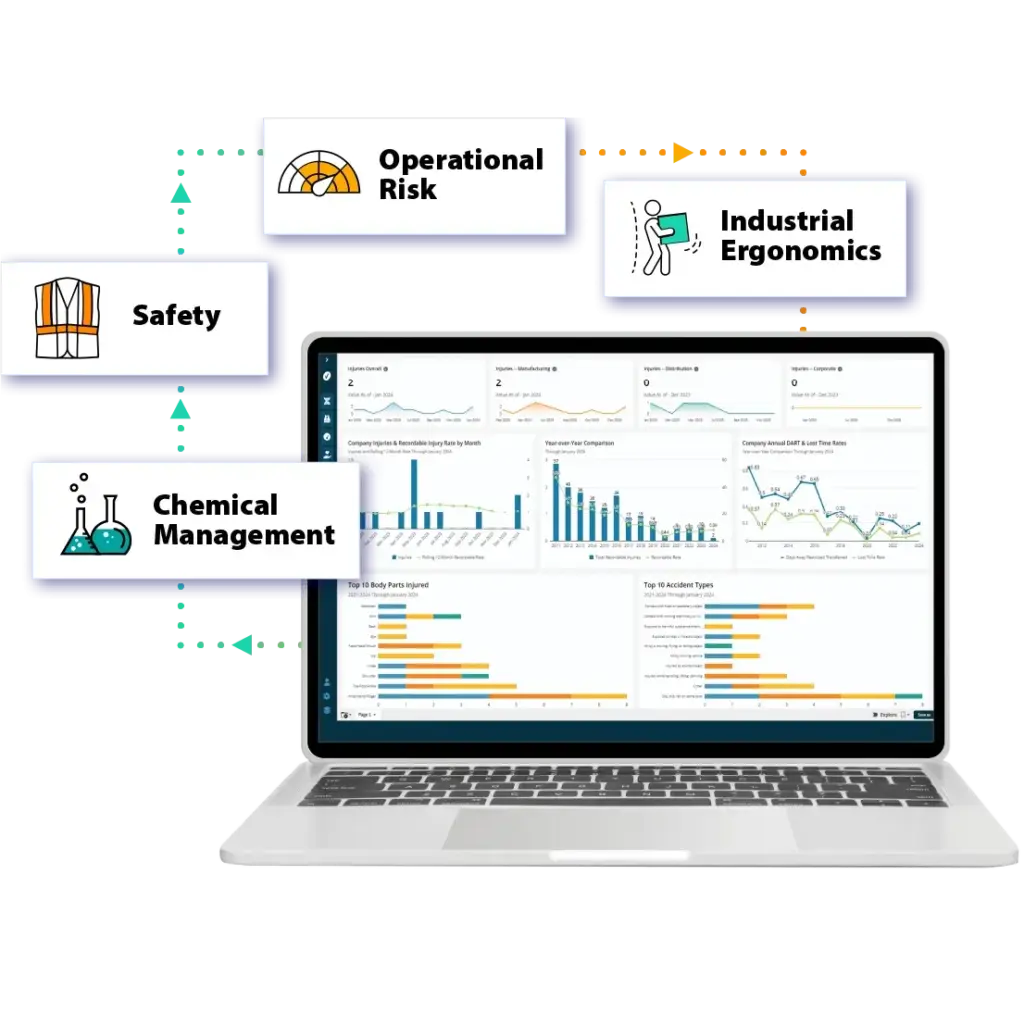

The EHS Software Revolution Has Begun

Introducing the VelocityEHS

Accelerate® Platform

The industry’s first truly integrated EHS platform on the market, streamlining Velocity’s Safety, Ergonomics, Chemical Management, and Operational Risk capabilities into one seamless solution.

Activations are underway. Secure your spot today!

Prevent Harm

Send workers home safe with solutions that cover a range of risks.

Drive Engagement

Reduce training time and simplify complex tasks with in-app guides.

Save Time

Free managers from tedious administration with centralized controls.

Be Predictive

Anticipate & address risk with real-time data you can trust.

Increase Visibility

Unite every level of your organization via shared dashboards & reports.

Embrace Innovation

Harness machine learning + AI & automation to deliver expert-level results, faster.

How can VelocityEHS help you with your JSAs?

The VelocityEHS Operational Risk Solution makes the JSA /JHA process faster, simpler and smarter.

Ditch paper and spreadsheets for a centralized software system that helps your team members easily document hazards and select controls, track corrective actions, and share results with other people — instantly. Standardized digital JSAs means more accurate, usable data to help your organization prioritize its safety and risk management efforts. Easy access to hazard information and preventive measures means a safer and more efficient workplace for everyone.

Job Safety Analysis (JSA) FAQ

Helpful Resources

What’s New in Operational Risk?

Check out the latest operational risk industry news, our latest blogs, and helpful training resources to ensure you stay ahead of the curve.

6 Key Benefits of Job Safety Analysis (JSA)

Guide

Operational Risk

Download this guide now to learn why JSA is essential to improving safety and reducing risk in your workplace.

Are Your JSAs Good Enough? Don’t Wait for a Workplace Incident to Find Out

On Demand Webinar

Operational Risk

Don’t wait until an incident happens before you investigate how well your JSAs are working. Learn the 5 key characteristics for effective JSAs.

JSA Software Helps Solve the Puzzle of Risk

Infographic

Operational Risk

Download this infographic to see how to make Job Safety Analysis more effective for your organization.

Schedule a Demo Today

You’re not just buying software or services—you’re investing in a partnership that empowers your team to proactively solve problems and move boldly into the future.