Complete Ergonomics

Management System

AI-driven ergonomics software, embedded expertise, and online training

Most Comprehensive Risk Assessment

New 3D model incorporates more data for greater accuracy & reliability

Standardize Ergonomics Across Your Business

Sustain & grow your ergonomics program to boost business performance

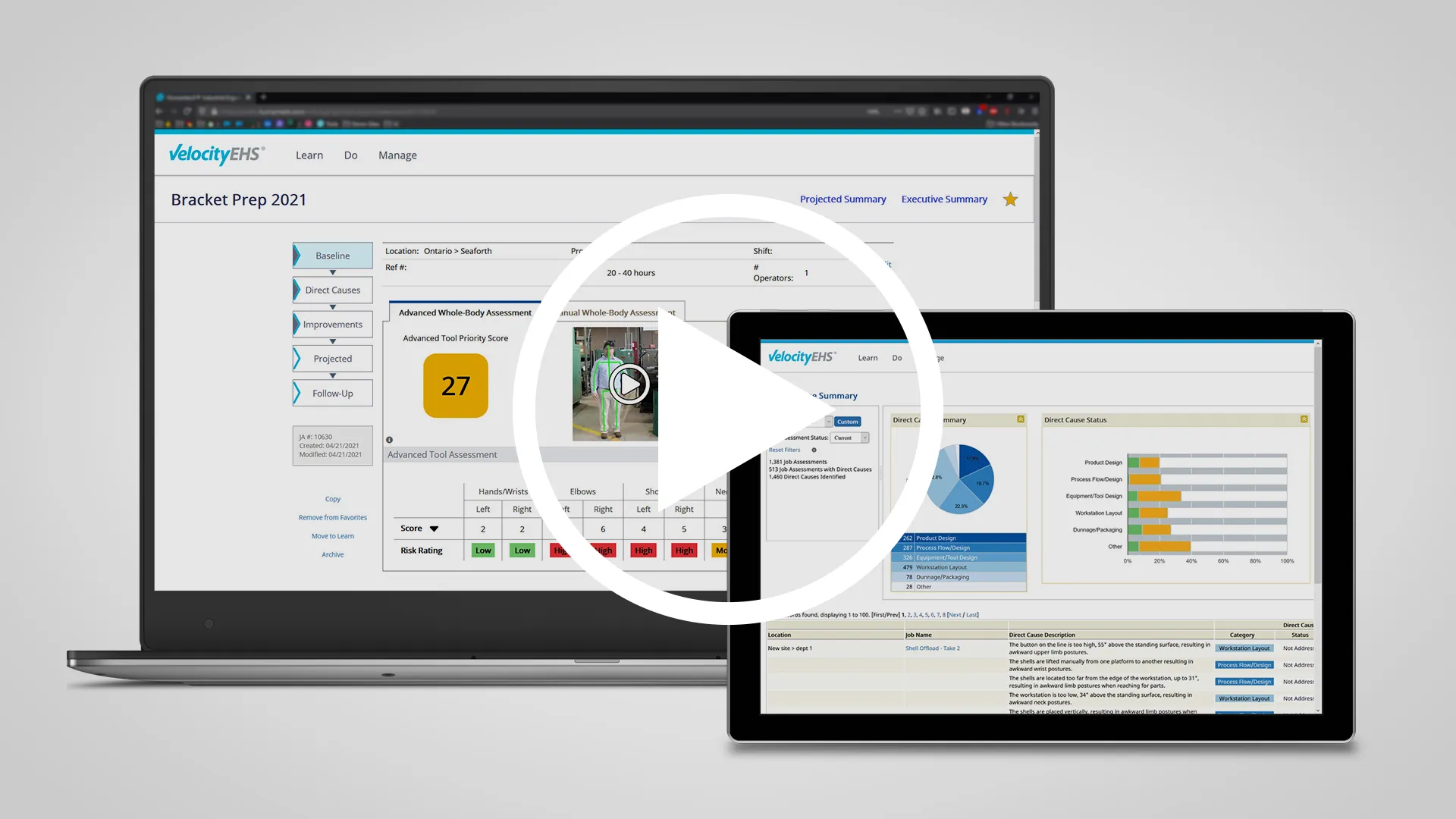

Industrial Ergonomics Now Has 3D!

The new 3D Model for Motion Capture in VelocityEHS Industrial Ergonomics improves upon the groundbreaking Humantech solution, acquired by Velocity, by providing the most comprehensive MSD risk assessment available, incorporating automatic scoring of wrist bending and back twisting, and even capturing data from hidden body segments. You’ll have greater confidence in your assessments and overall ergonomics process.

Watch the video to learn more.

Capabilities

Ergonomics software capabilities optimized for your specific work environment

AI-Driven MSD Risk Assessments

Dashboards & Reporting

Risk Reduction Index

AI-Driven MSD Risk Assessments

Dashboards & Reporting

Risk Reduction Index

Watch the 4-min Quick Tour to see what goes into VelocityEHS Ergonomics.

Benefits of VelocityEHS Ergonomics

Systematically Addresses

MSD Risk

- Complete system to accurately identify, quantify, & control the most common risk for workers.

- Track progress, monitor effectiveness and apply lessons learned from improvements.

Democratizes

Ergonomics

- 3D Model for Motion Capture assessments for greater accuracy & reliability.

- Embedded expertise to help identify the right root causes and risk controls.

- Online training in multiple languages to educate & reinforce ergonomics principles.

Sustainable and

Scalable

- Supports a continuous improvement approach, ensuring effectiveness & accountability.

- Visual dashboard to identify trends, reporting to track & share progress enterprise-wide.

“The cost of one injury compared to what we’re paying for [VelocityEHS Industrial Ergonomics]… There’s no comparison.”

![]()

—Nicholas Boots, Quality and EHS Manager

Tools to Enhance Your Ergonomics Process

ROI Calculators

Building the business case for ergonomics is the key to getting your program and job improvements funded. Speak in terms your leadership will understand with these estimators, developed by our in-house board-certified professional ergonomists.

Program Self-Assessment

Easily gauge the current state of your ergonomics program to find gaps and strengths and ensure your process is moving in the right direction. Get personalized results and custom recommendations for actionable next steps.

Settings & Industries

Ergonomics software capabilities optimized for your specific work environment

Manufacturing

No matter which assembly or manufacturing process you use, your workers are still your most valuable investment. Keep your industrial athletes from the risks of developing soft tissue injuries with a consistent and sustainable ergonomics process.

Food & Beverage

Repetitive jobs, wet/cold environments, sanitation requirements, and a complex supply chain make the food and beverage industry ripe for MSD risk. Our simple and systematic tools engage employees and gain the attention of management to drive steady and continuous improvement.

Automotive

The unique aspects of the automotive industry are also the keys to success when addressing workplace ergonomics. Our approach incorporates continuous improvement with sound ergonomic design guidelines and consistent assessment methods to help you realize solid results.

Aerospace

Manual processes, long cycle times, and non-standard work can pose a challenge for addressing soft-tissue injuries in the aerospace industry. You need a flexible system that’s simple, fast, and keeps employees healthy and productive. We’ve got you covered.

Chemical

In the chemical industry, with varied work settings, the workplace improvement process must be shared by many. VelocityEHS Ergonomics makes it easy to get others involved. Our simple design engages management to end-users and drives participation.

Pharmaceutical

Diverse work environments and heavy regulations make the pharmaceutical industry one of the more difficult in which to introduce workplace changes. Our ergonomic design guidelines and process-driven approach will help you get it right the first time and prevent injuries before they happen.

Distribution

Activities common to distribution and warehousing like lifting, pushing, and carrying can easily lead to overexertion injuries, costing companies billions. An effective, data-driven ergonomics process has a profound impact on maximizing human performance and improving the bottom line.

Laboratory

The laboratory environment poses unique challenges resulting from the use of specialized equipment. Knowing how to adjust workstations to fit the employee, and using proper work practices can improve overall comfort, accuracy, and productivity at work.

Field Services

When your work environment changes often, it’s hard to assess the risk of soft-tissue injuries. A consistent set of standardized tools plus the knowledge to quickly evaluate the workplace are critical. Our solutions give you a process that won’t fail, no matter where the work is.

Process

Manual material handling, high forces, tight spaces, and extreme conditions are just some of the challenges faced by workers in process industries. Proper tooling, effective ergonomics training, and good job design are a must to maintain worker health and safety.

The EHS Software Revolution Has Begun

Introducing the VelocityEHS

Accelerate® Platform

The industry’s first truly integrated EHS platform on the market, streamlining Velocity’s Safety, Ergonomics, Chemical Management, and Operational Risk capabilities into one seamless solution.

Activations are underway. Secure your spot today!

PREVENT HARM

Send workers home safe with solutions that cover a range of risks.

DRIVE ENGAGEMENT

Reduce training time and simplify complex tasks with in-app guides.

SAVE TIME

Free managers from tedious administration with centralized controls.

BE PREDICTIVE

Anticipate & address risk with real-time data you can trust.

INCREASE VISIBILITY

Unite every level of your organization via shared dashboards & reports.

EMBRACE INNOVATION

Harness machine learning + AI & automation to deliver expert-level results, faster.

Have questions about the VelocityEHS Accelerate® Platform?

Helpful Resources

What’s New in Ergonomics?

Check out the latest ergonomics industry news, our latest blogs, and helpful training resources to ensure you stay ahead of the curve.

Getting Value from Your Ergonomics Assessments

On Demand Webinar

Ergonomics

This session provides simple-to-follow tips to move from completing MSD risk assessments to establishing an effective ergonomics job improvement process.

VelocityEHS Continues its Mission to Reduce Workplace Injuries by Establishing New Ergonomics Partner

Posted on January 14, 2025

VelocityEHS®, the global leader in EHS & ESG software solutions, announces a strategic partnership with Sandalwood Engineering and Ergonomics, a leading professional…

Building an Effective Ergonomics Team

Ergonomics

An effective ergonomics process requires a diverse and dedicated team to assess, prioritize, and address musculoskeletal disorder (MSD) risks. However, deciding which…

Partner with the most trusted name in the industry

Stress less and achieve more with VelocityEHS at your side. Our products and services are among the most recognized by industry associations and professionals for overall excellence and ease of use.